AMB Controllers

Sophisticated Control Software

With the industry’s most sophisticated software, Waukesha Magnetic Bearings controllers provide advanced dynamic control algorithms, remote diagnostics and adjustment, and enhanced investment protection using intelligent trip technology.

Magnetic bearing control systems maintain and adjust the position of the rotor by varying the current in the electromagnets in response to signals from the position sensor. This system defines the stiffness and damping of the magnetic suspension.

In addition, the controls interface with other plant systems to allow proper start-up, operation and shutdown of the system.

High Processing Performance

The high processing performance of Waukesha Magnetic Bearings digital controllers allow for complex algorithms that provide superior dynamic efficiency, usability, ergonomics and noise immunity.

Built-in Condition Monitoring

The controllers’ built-in condition monitoring provides comprehensive diagnostics for bearing performance, and remote connectivity capabilities allow for remote commissioning, monitoring and diagnostics – without the need for on-site support.

Vibration Attenuation Software

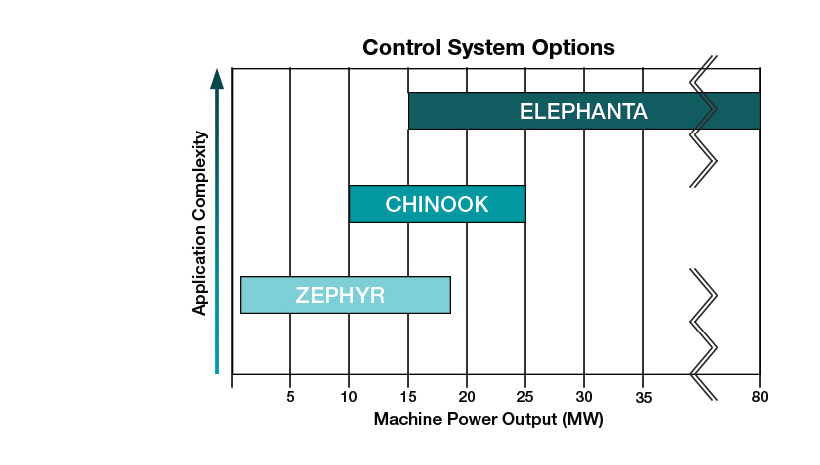

Controller Power Ratings

Waukesha Magnetic Bearings offers controllers suitable for turbomachinery applications from 50 kW to 80 MW. Our Elephanta® controller is four times more powerful than the competition and offers up to 7-axis control, while the Zephyr® controller is available in an on-skid configuration, reducing the cost and complexity of installation.

Automated Commissioning

Own the commissioning process with Automated Commissioning, exclusively from Waukesha Magnetic Bearings.

Automated Commissioning is a toolkit of automated scripts, implemented via standard internet protocol, that speeds up commissioning and maintenance and transfers control to the OEM or end user.

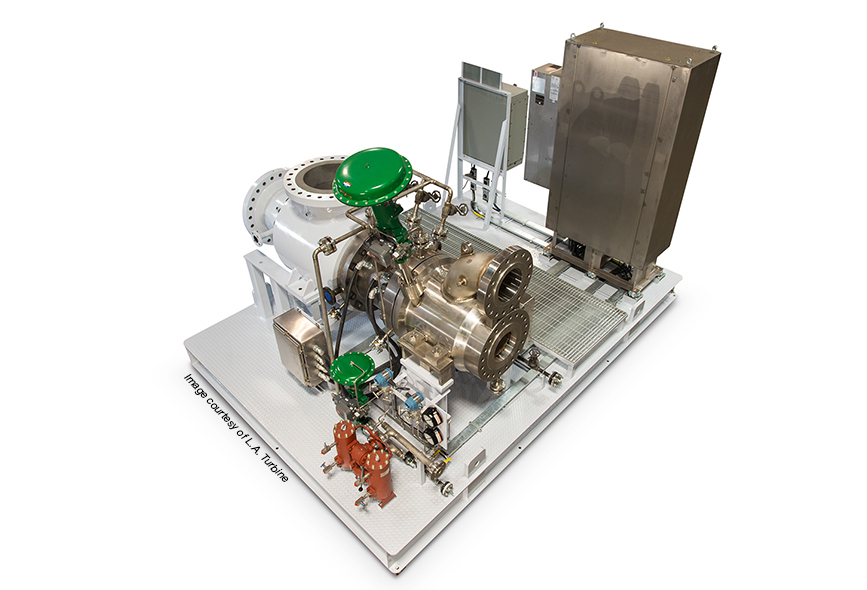

Industry-First Skid-Mounted Controller

Waukesha Magnetic Bearings has introduced the industry’s first skid-mounted AMB control system – certified for Class 1/Div 2 hazardous area installation. The high-tech digital signal processors and control algorithms of the Zephyr 5-axis controller are combined with the benefits of simplified plant design and CapEx savings.

AMB Hardware

Waukesha Magnetic Bearings provides robust bearing designs for high reliability and availability in a range of operating environments. Our sealed magnetic bearings can be immersed in mildly corrosive process fluid environments, while our canned magnetic bearings are designed for immersion in the most extreme corrosive and abrasive environments.

Support and Service

Waukesha Magnetic Bearings service and support reduces magnetic bearing operating expenses and logistical headaches. Customized training courses equip OEMs and end users to perform specified maintenance and sophisticated fault finding, while our AMB system upgrades can extend plant operating life and improve reliability and efficiency.