Polymer Bearings for Electrical Insulation, Water Lubrication

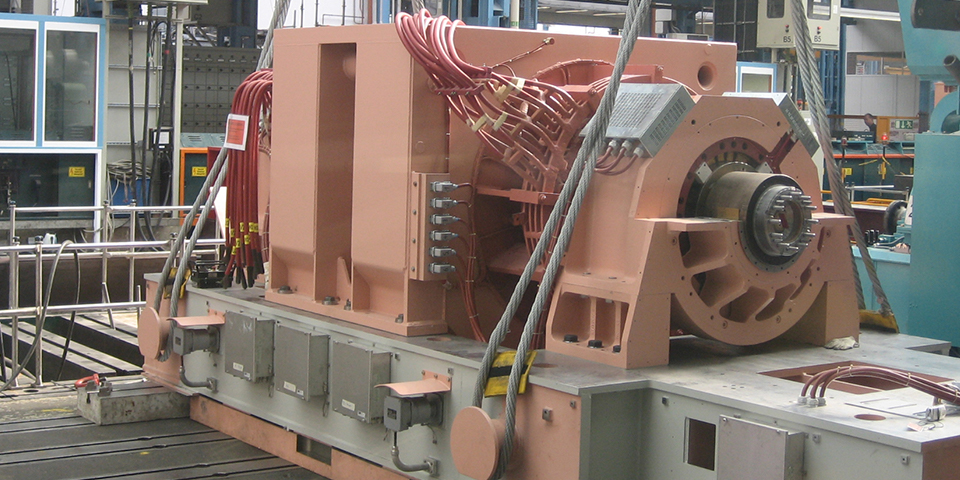

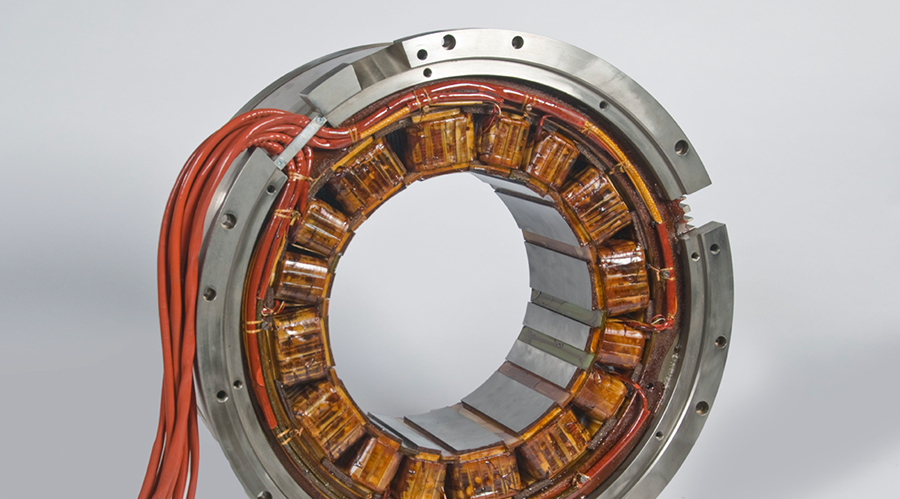

The high electrical resistance of polymer bearing surfaces can prevent damaging currents from passing through the bearing and housing, eliminating the need for a separate insulation layer. This capability is especially valuable for preventing high frequency circulating currents in motors with variable speed drive.

In water-filled motors, polymer bearings provide an inert solution with high load capacity, without the need for external bearing lubrication. The bearings can be lubricated by the same water cooling the motor.

Read More