Pumps

Bearings Optimized to Your Operating Conditions

Pumps are built in a wide variety of sizes and types, from nuclear primary to electric submersible – demanding a wide range of bearing designs. Whatever the design, Waukesha Bearings can provide an optimized bearing solution.

Among our specialties is the application of non-oil-lubricated bearings, which can improve pump performance and reliability, eliminate lubrication oil systems and shaft seals, reduce pump size and weight, reduce power consumption, eliminate the potential for product contamination, and eliminate potential leakage of a hazardous fluid to the environment.

Bearing Design

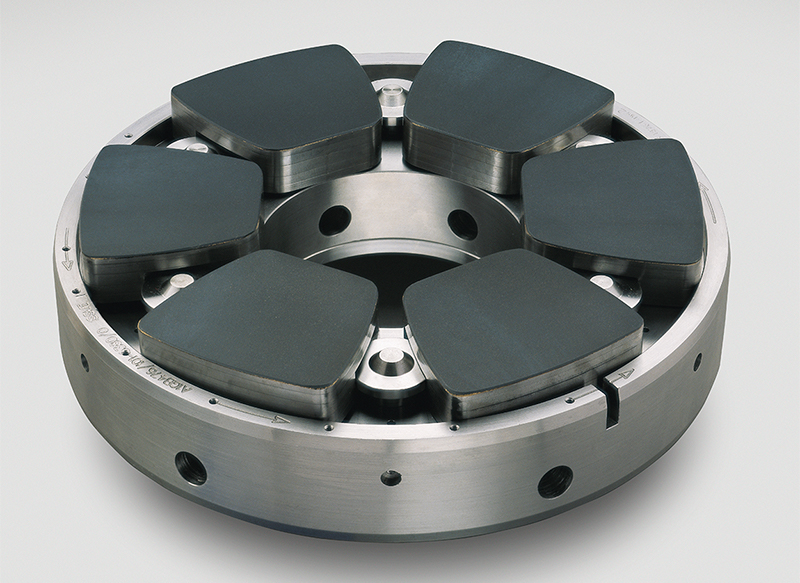

For larger pumps, the typical bearing design is an oil-lubricated tilt pad bearing with babbitt pads and fitted with seals. Steel pad backings can be upgraded to copper chrome backings to increase the amount of heat conducted away from the bearing surface.

Smaller pumps frequently use water or process lubrication to simplify the design; their bearings typically feature polymer or ceramic materials.

Click the links below to read more about our specialized design features for journal and thrust bearings.

Process Lubrication

In applications lubricated by water or process fluid, bearing materials need to be both chemically resistant to the fluid and able to operate with thin films.

With clean fluid, polymer bearings provide an inert solution with high load capacity. Solid polymer bearings can handle loads up to 10 MPa (1500 psi) in clean water and have been used successfully in reverse osmosis pumps, boiler feed pumps and mine-dewatering pumps.

Where abrasives are present, ceramic/cermet bearings provide a durable option, without requiring a filter system. For this reason, they have been used extensively in water injection pumps in the North Sea.

Ceramic/cermet bearings are also resistant to most chemicals and retain their mechanical properties and load carrying capacity over a greater range of temperatures than polymers.

Polymer Capabilities Ceramic Capabilities

Expanded Capabilities in Oil Lubrication

Polymer and ceramic bearings can also be applied to oil-lubricated pumps.

Polymer-lined bearings operate on very thin hydrodynamic films to meet the demand for high load capacity and long life, and are widely used in multi-phase booster pumps and water injection pumps.

Ceramic bearings are used successfully in crude oil booster pumps, cryogenic pumps and subsea pumps.

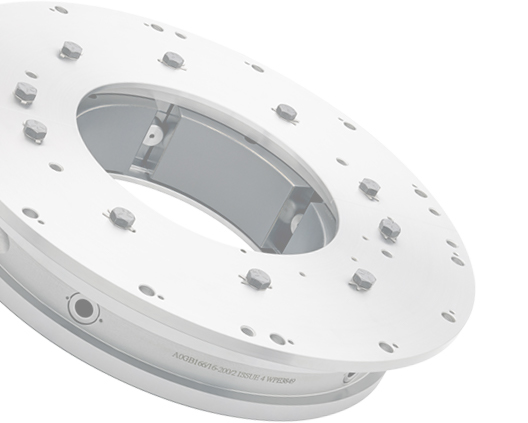

Thrust Bearings for ESPs

Waukesha Bearings offers a range of material options to maximize thrust bearing life in electric submersible pumps (ESPs), increasing efficiency, production and the operating life of the pump.

Pump Bearing Solutions

Flexure Pivot® Journal Bearings

Active Magnetic Bearings

Downloads

- Plain Bearing Options for Pumps (World Pumps, June 2002)

- New Bearing Designs Meet Demands for Extended Pump Operating Life (Modern Pumping Today, February 2015)

- Present Limits of Operation of Product Lubricated and Magnetic Bearings in Pumps (Proceedings of the 14th International Pump Users Symposium, 1996)

- Bearings for Pumps (11th International Pump Conference, Cambridge, April 1989)