Turboexpanders

Advancing the Possibilities of Magnetic Bearings

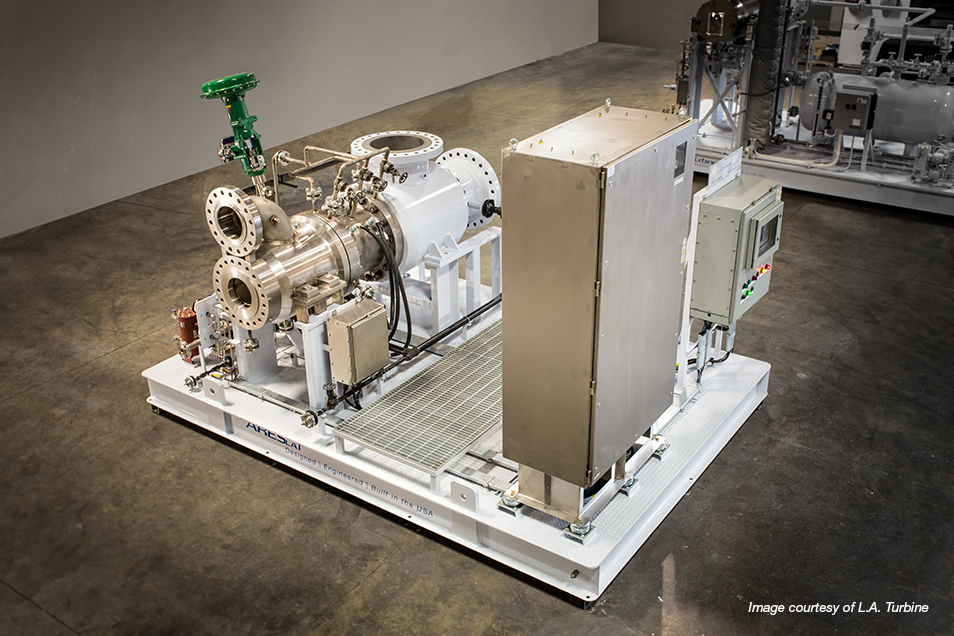

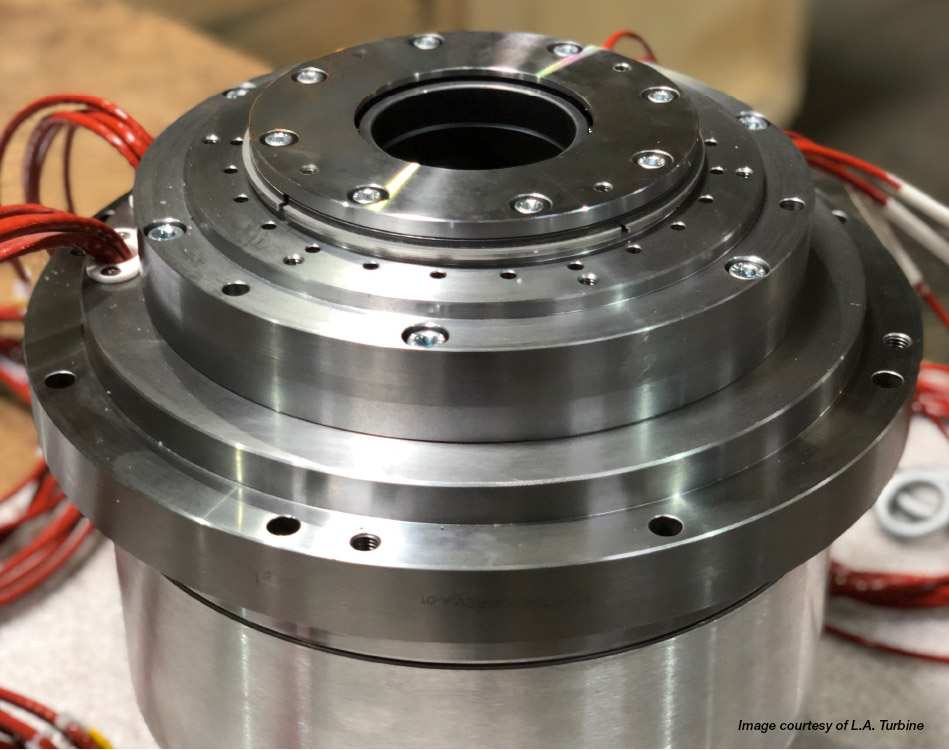

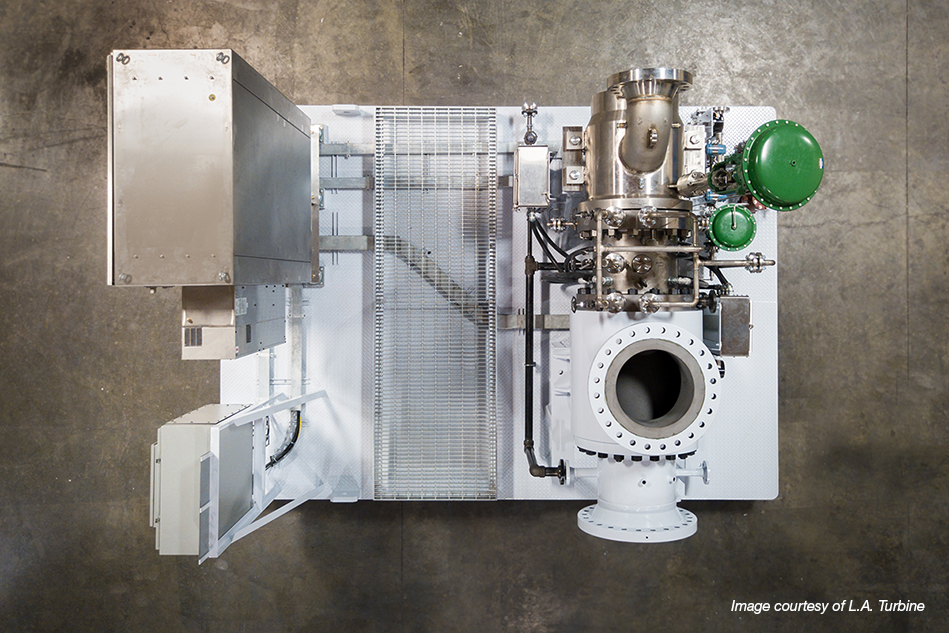

Waukesha Magnetic Bearings is proud to be partnering with L.A. Turbine (LAT) to bring the benefits of active magnetic bearings to turboexpander operators. As part of the LAT ARES AMB turboexpander-compressor, we have introduced the industry’s first skid-mounted AMB control system.

Gas processors benefit from lower CapEx, faster commissioning, decreased maintenance, a smaller footprint, improved site layout, temperature and performance flexibility, and a more environmentally friendly machine.

Hazardous Area Installation

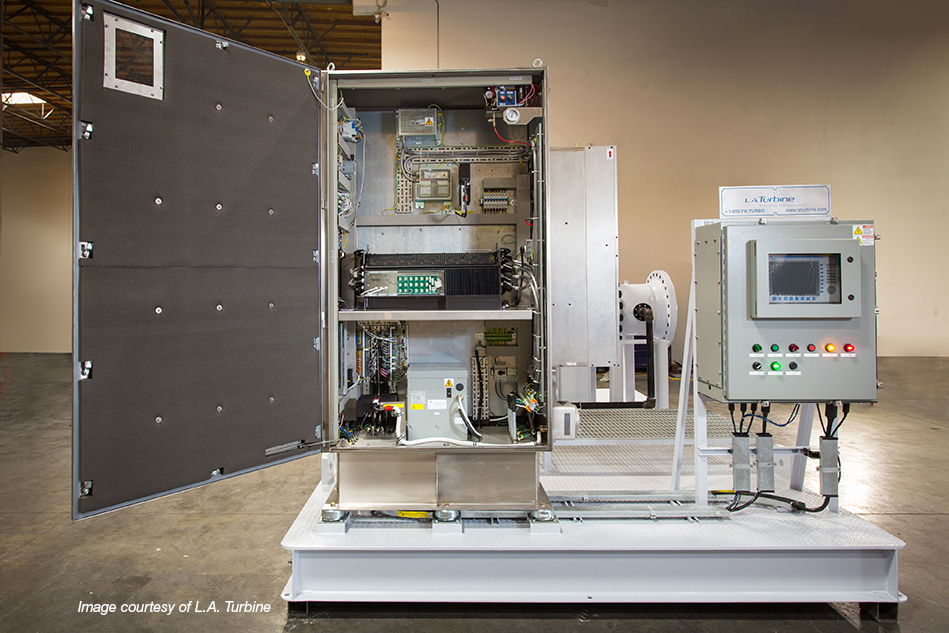

In a conventional hazardous area installation, the AMB controller is installed in a control building in a safe area away from the machine skid, connected by expensive cabling. Costs are incurred for the cables, their design and installation. In addition, OEM testing is typically not performed with the job cables, requiring recommissioning of the AMB system at the end user site.

The Waukesha Magnetic Bearings skid-mounted AMB controller, certified for Class 1/Div 2 hazardous area installation, eliminates the costly AMB cables and simplifies plant design. Moreover, the turboexpander is ready for operation upon delivery to the site.

Built-in Condition Monitoring

Operators also benefit from the ability to perform remote commissioning, monitoring and tuning of machine performance due to the high-tech digital signal processors and control algorithms of the Waukesha Magnetic Bearings Zephyr® 5-Axis Controller.

Lower Total Cost of Ownership

AMB systems from Waukesha Magnetic Bearings provide cost savings throughout the equipment life cycle.

Advantages

- Precise, reliable operation without the complexity of a lubrication oil system

- Condensed plant footprint

- Simplified installation and operation

- Standardized design to achieve greater than 80% efficiency for all cases

- Pre-engineered and tested solution

- Controllable rotordynamics

- Easy customer implementation of Automatic Thrust Balancing system

- Secure remote connectivity for monitoring, tuning and diagnostics

- Integration with customer IIoT platforms

- Flexible production output capacity

- Wide temperature operating range

- Short build-to-delivery timeframe

- Faster start-up and commissioning

- Reduced CapEx

- Minimal maintenance costs

- Eliminates need for on-site support

- Class 1 / Division 2 hazardous area certification

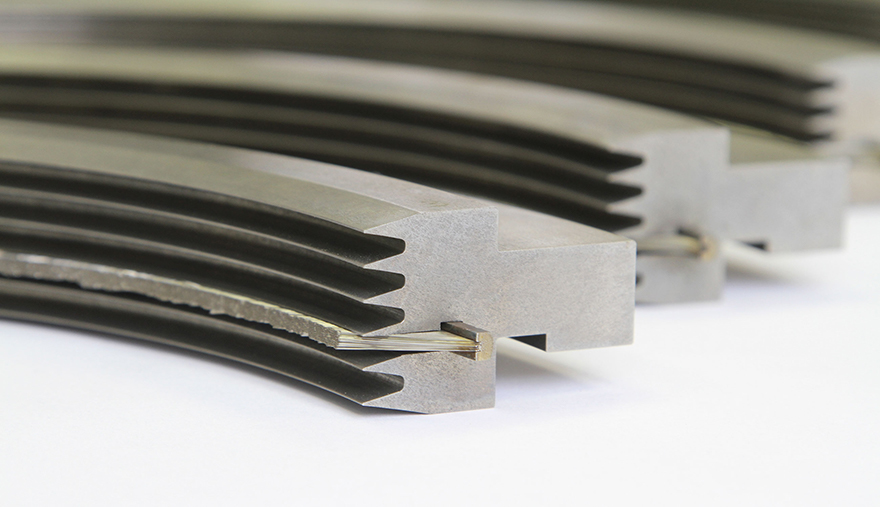

Flexure Pivot® Journal Bearings

For high-load, high-speed, small-diameter shafts, our Flexure Pivot tilt pad design achieves low cross-coupling and high stability, while eliminating the pivot wear that can cause degradation in performance over time.

Leading Vibration Solutions

With our in-depth understanding of system rotordynamics, Waukesha Bearings offers proven solutions to improve stability and control vibrations. Chief among those solutions, our integral squeeze film damper (ISFD® technology) provides highly engineered damping and stiffness to maximize energy dissipation at the bearing locations.

Brush Seals

Waukesha Bearings brush seals can minimize leakage gaps and increase operational efficiencies. The compliancy of a brush seal allows sealing clearances to be significantly reduced, while its low profile allows simple integration with labyrinth seals.