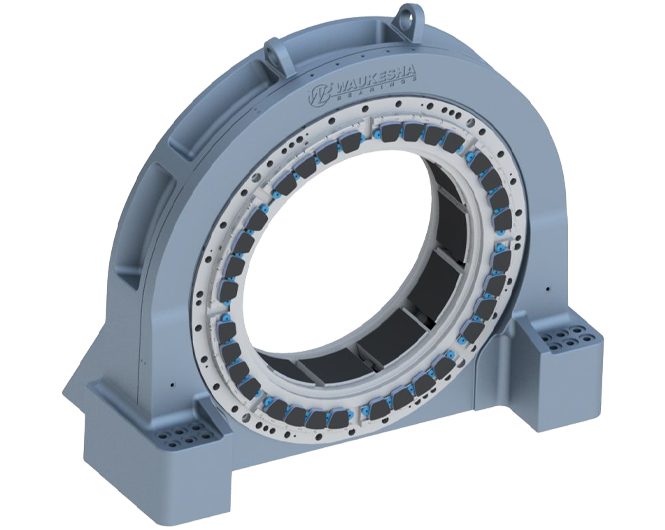

NordAlign™ Fluid Film Bearings

Optimized performance for wind applications

Waukesha Bearings collaborated with equipment OEMs and leveraged world-class material development and testing capabilities to develop the NordAlign fluid film bearing.

This game-changing technology improves main shaft reliability, cuts costs, and is easy to install. NordAlign bearings allow for almost seamless uptower exchangeability, eliminating the costly expense of jack-up vessels and cranes.

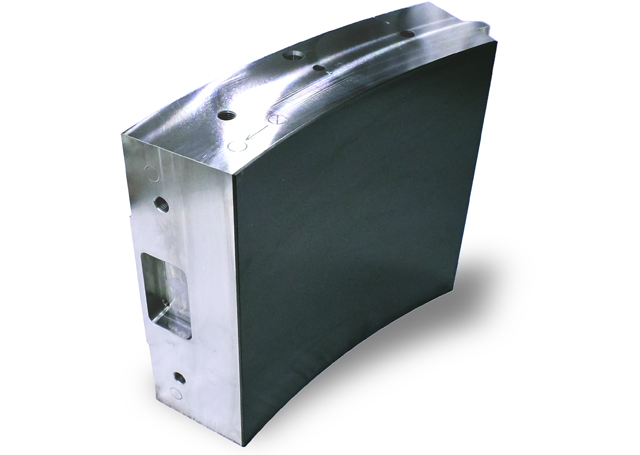

The modular design can scale up to fit larger wind turbines, resulting in cost savings. The optimized pad shape easily integrates into the nacelle and provides advanced bearing performance within a broad range of operating conditions, including assembly, low speed/idling, and extreme events. And, the tilt pad dynamically adjusts to radial and axial shaft movements to optimize load distribution for longer bearing life.