Advanced Bearing Systems

As the demand for energy – and carbon-neutral energy – grows around the world, so do the demands put on the equipment operating in the oil & gas industry.

Depleting oil and natural gas reserves require higher performing rotating equipment that places extraordinary demands on rotor-bearing systems. Emerging hydrogen and hydrogen-blend applications also raise performance requirements.

Expertise in Oil & Gas Applications

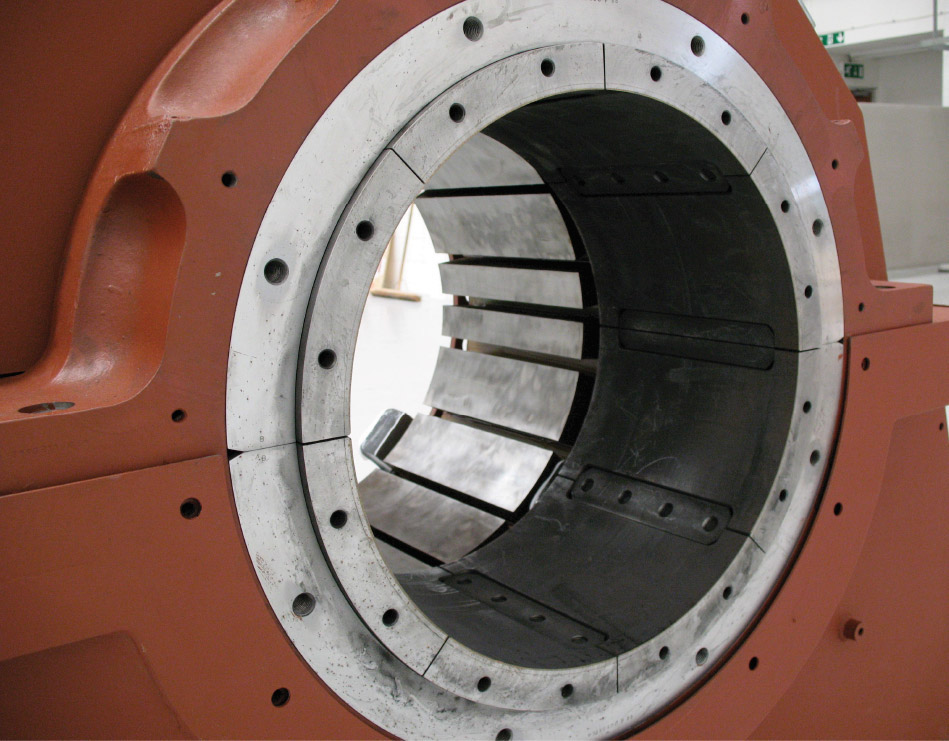

Fluid film bearings and magnetic bearing systems from Waukesha Bearings are used at almost every stage of oil and gas production – in pumps, compressors, turboexpanders and motors used in the extraction, refining, transport and storage of oil and natural gas. In partnership with machine designers, Waukesha Bearings engineers apply extensive industry expertise, proven design codes and industry-leading technologies to deliver bearing solutions tailored for specific application requirements.

Proprietary bearing design features, advanced material options and robust magnetic bearing solutions all help drive equipment to new levels of performance, reliability and availability, particularly in remote and subsea oil & gas applications.