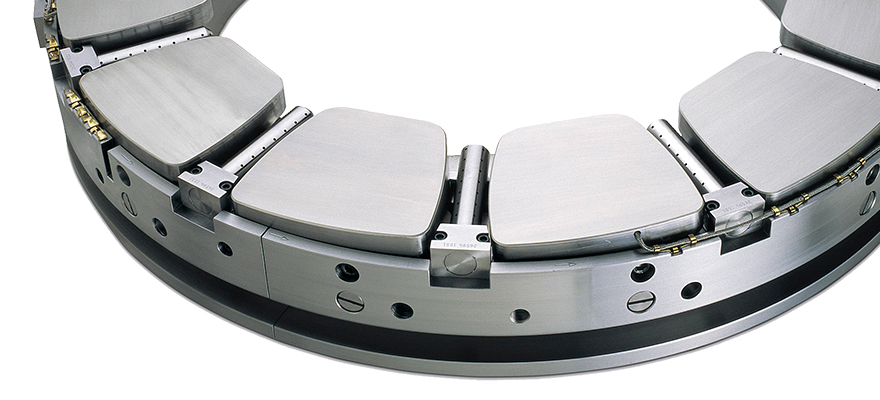

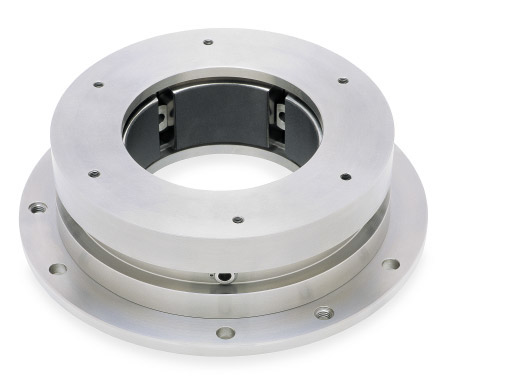

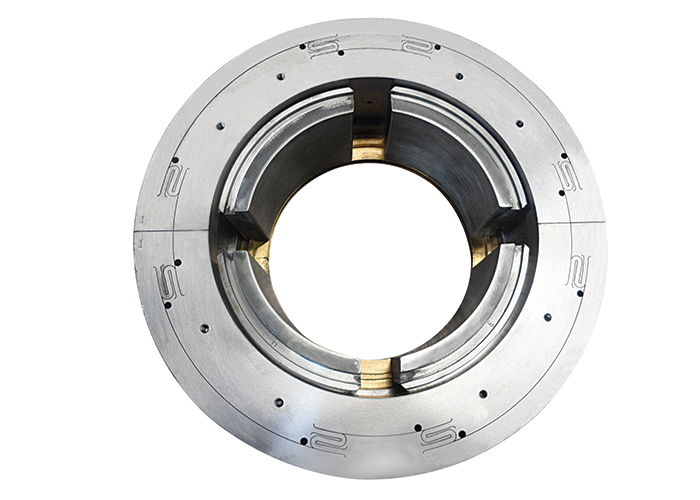

Tilt Pad Bearings

Depending on size, gas and steam turbines typically use tilting pad journal and thrust bearings, sometimes in combined assemblies. ‘Directed Lubrication’ is usually employed to minimize power loss and oil flow and to reduce pad surface temperatures.

To handle the high speeds and high loads, gas turbine thrust bearings often require the use of copper chrome (CuCr) backing material and assured pivoting mechanisms.