Case Study

Magnetic Bearings Exceed 95% Availability in Pipeline

Located in the Leningradskaya region of Russia, Gazprom’s Compressor Station Elizavetinskaya-1 is a key point of the Gryazovets-Vyborg Pipeline and provides gas to European consumers via the Nordstream Pipeline and to the northwestern region of Russia.

Due to bitter experience with other compressor stations in frigid locations, Gazprom sought ways to improve their compressors’ operations by seeking a new supplier of active magnetic bearings (AMBs). Their goal was to improve availability and reliability, meaning uninterrupted gas deliveries to its consumers.

In addition, they wanted to eliminate process oil in the bearings to reduce required maintenance and potential fire hazards throughout the 900 kilometers of pipeline and 55 billion cubic meters of gas.

Solving the Challenge

Gazprom began operation of compressors with AMB systems in the early 2000’s. Since then, they had worked with one local supplier and had little success. With low reliability and the low quality of local supplier’s equipment, customers weren’t receiving the gas in appropriate volumes, and with cold temperatures, repairs often took longer.

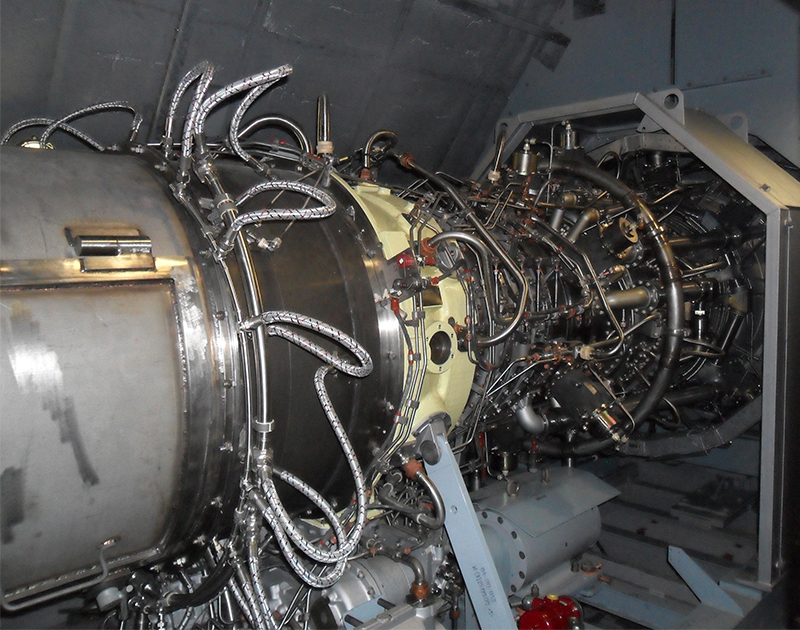

In late 2008, Gazprom partnered with Mitsubishi Heavy Industries (MHI) and Waukesha Magnetic Bearings to develop a more reliable system. MHI provided a 16 MW gas compressor and Waukesha supplied the AMB system for the compressor. The AMB system consists of mechanical components and magnets, auxiliary bearings, with digital components.

The four gas compressor units with WMB systems have been installed at Elizavetinskaya-1 site and were successfully commissioned in early 2012. All components were certified according to Russian standards (GOST).

When Performance Affects Millions

Gazprom results showed immediate improvement over the other system in operation. After 10,000 hours of operation, the availability exceeds 95%. This increased reliability means continuous gas deliveries and energy security to consumers in a sustained manner. The system also provided simpler integration with the compressor station due to the digital output/input from the digital cabinet, versus previous experience with analog cabinets.

Additional benefits included time-savings with an easier commissioning and tuning process, remote monitoring, and adjustment capabilities, higher processing performance that allows for more complex algorithms that provide higher dynamic efficiency, improved usability and ergonomics, and noise immunity. The success of the first installation of four sets has led Gazprom to approve the Waukesha AMB system for future projects.

“By creating new routes for our European consumers, it is a guarantee that their gas demand will be met and the EU countries’ energy security will be reinforced in a sustained manner” said Alexey Miller, Gazprom.

Application Details

- Industry: Oil & gas transportation and production

- Four 16 MW gas compressors

- Four active magnetic bearing systems

- Auxiliary bearings

- Dual-bay Chinook® AMB controller

- GOST certification to comply with Russian standards

Advantages

- Proven availability exceeds 95% in four compressor installations

- Reduced maintenance cost by increasing mean time between repair (MTBR) from three months to over five years

- Lower total cost of ownership due to higher reliability and lower maintenance costs

- Environmentally friendly – eliminating oil from compressor

AMB System Capabilities

Magnetic bearing systems can accommodate a variety of rotating equipment. Applications include steam turbines, turboexpanders, pumps, and compressors. Wherever you need high availability, remote connectivity, and access, or an oil-free solution, Waukesha Magnetic Bearings is ready to provide the solutions.