Tilt Pad Journal Bearings

Custom Engineered

Waukesha Bearings custom engineers each tilt pad journal (radial) bearing to not only handle the required loads but also provide optimum static and dynamic performance.

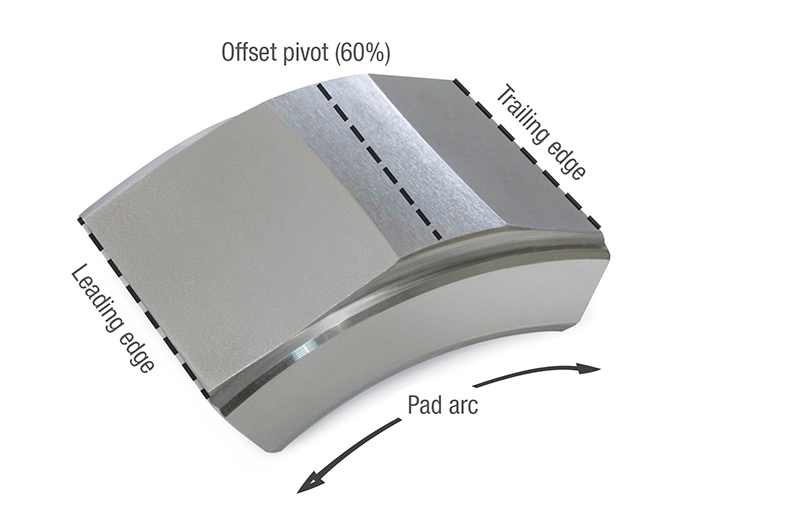

Pad arc, pivot offset, bearing clearance, length of the bearing, and preload are each carefully considered, as they can affect such factors as power loss, temperature and dynamic performance.

Bearing Design

Tilt pad journal bearings typically include four or five pads. The pivot type is selected based on requirements for life of the pivot, stiffness, ease of pivot tilt in one or more directions, and industry requisites. Common pivot types include point contact, line contact, ball and socket, and Flexure Pivot®.

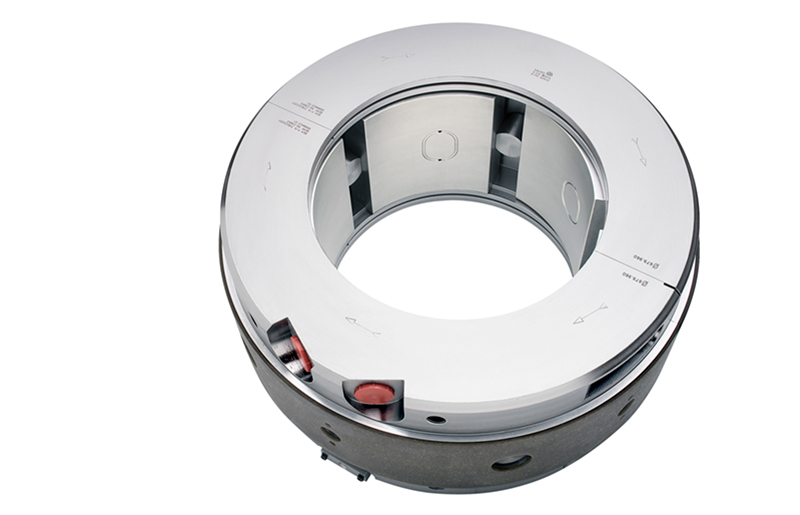

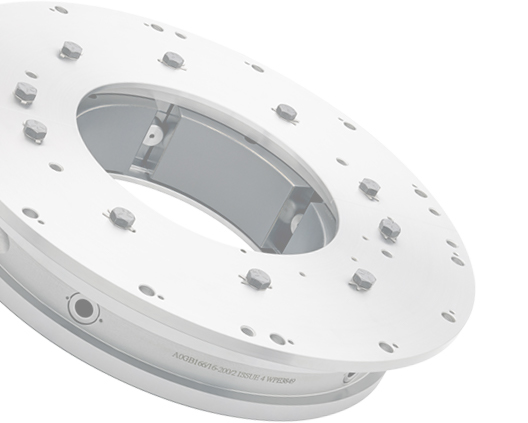

Waukesha Bearings tilt pad journal bearings are available with one-piece or split housings. Temperature sensors are typically installed in the loaded journal pad(s).

Lubrication and Seals

‘Directed Lubrication’ minimizes power loss and oil flow while keeping pad temperatures low. Oil flow is controlled by nozzles between each pad with the oil exits from each end of the bearing having only large clearance baffles.

While the standard system described above is ideal for the bearing itself, the machine location in which a bearing is installed sometimes requires restriction of the end flow, either at one or both sides.

Floating seals reduce the flow along the shaft to a minimum; if two floating seals are used, the main flow is directed through an orifice outlet usually at the bottom of the bearing.

Knife edge endplates, while less effective than floating seals, offer some control of end leakage.

Advantages

- Hydrodynamically stable at high speeds

- Accommodate varying conditions

- Less sensitive to load direction or shaft misalignment than fixed profile bearings

- Optimized lubrication for minimum power loss and pad temperature

- Compact designs of combined thrust and journal bearings available

- Advanced materials available to withstand high speeds, loads and operating temperatures, as well as special lubricant requirements

Specialty Designs

Tilt Pad Thrust Bearings

The Waukesha Bearings product portfolio also includes high-performing tilt pad thrust bearings, engineered to provide the most reliable, efficient machine performance.