Maxalign Bearings

Greater Capabilities

As rotating equipment has grown and efficiency requirements increased, the Maxalign® bearing has answered the imperative for a bearing with greater capabilities for handling misalignment and reducing power loss.

With 30+ years of proven experience and design flexibility on large rotating plant equipment, along with field experience at high loads and sliding speeds, Waukesha Bearings and the Maxalign design have become the clear choice of the industry.

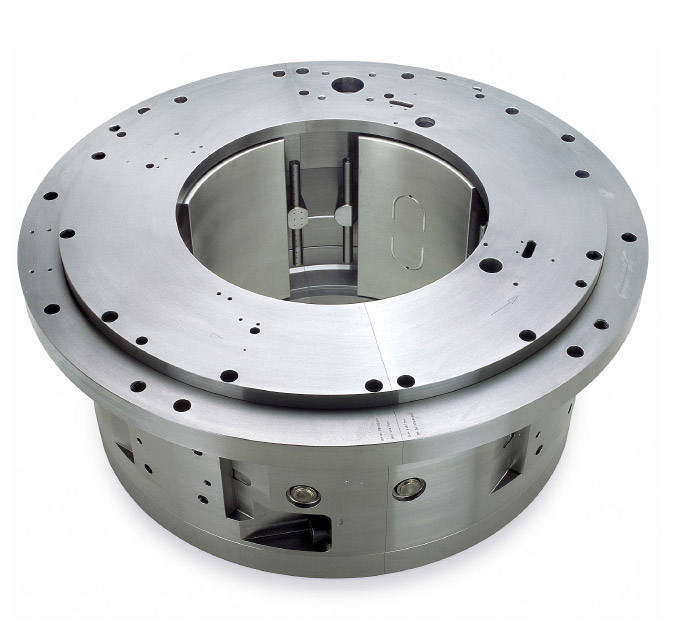

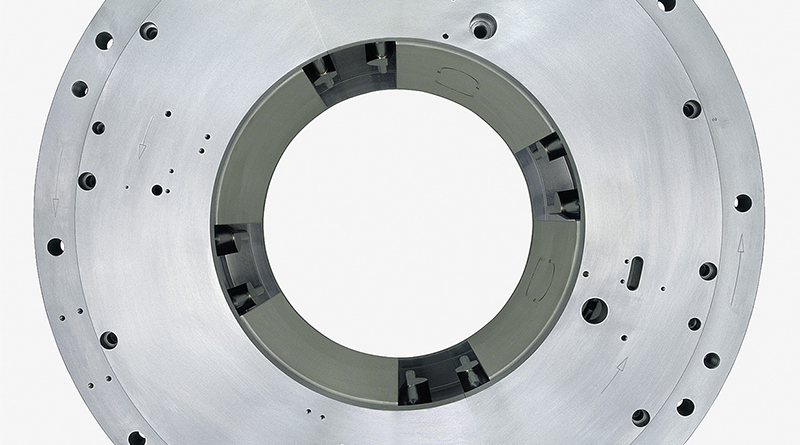

Designed for Large Shafts

For large shaft sizes (300 mm [11.8″] and up) it is usually necessary to consider improved forms of pad pivot design to ensure high stiffness, combined with the ability to tilt and align.

The Maxalign bearing features a specialized ball and socket pivot that provides high stiffness and is highly adaptable to shaft misalignment caused by mechanical loading or thermal effects in large rotating equipment.

Meanwhile, ‘Directed Lubrication’ eliminates the need for seals, minimizing power loss and keeping pad temperatures low. As part of a ‘Directed Lubrication’ system, our patented trailing edge cooling can lower Maxalign bearing temperatures to permit operating speeds in excess of 100 m/s and loads above 3 MPa, without compromising bearing life or safety margin.

Features

- Patented ball and socket pivot support

- 60˚ arc, 4-pad or 5-pad, offset pivot

- ‘Directed Lubrication’ technology with no sealing necessary

- Patented trailing edge cooling

- Hydrostatic jacking

- Suitable for shaft sizes 300 mm (11.8″) and up

- Available in combination with thrust bearings

Advantages

- Reduced oil flow and power loss to help improve machine efficiency

- High stiffness

- Adapts to shaft misalignment

- Verified performance and predictive capability

Case Study

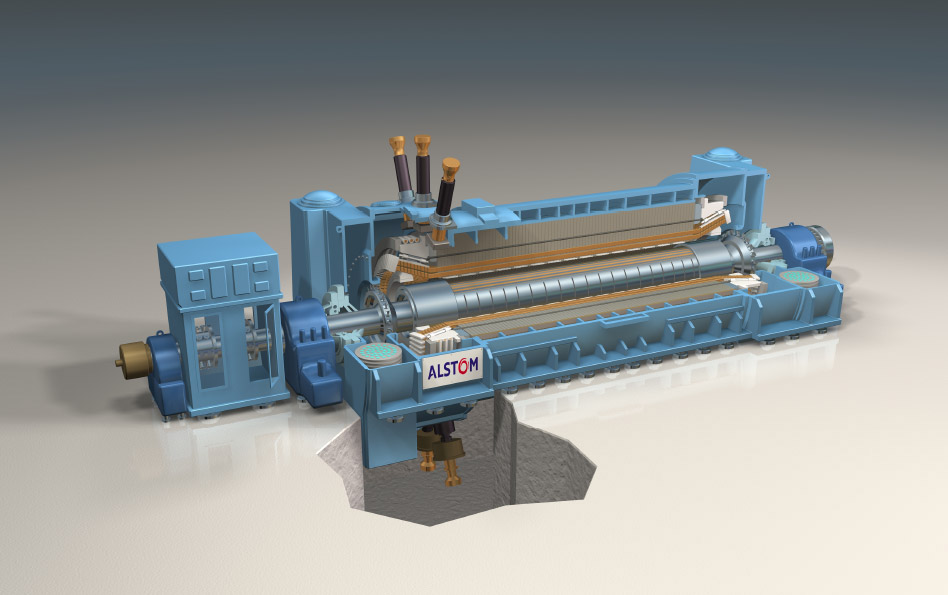

Maxalign Bearings Reduce Spiral Vibration on Turbo-generators

When Alstom Power identified a phenomenon of spiral vibration close to the trip level on a 450 MVa hydrogen-cooled generator, our proprietary predictive tools and extensive industry experience on equipment of this size made Waukesha Bearings the clear choice to design and manufacture a drop-in bearing replacement.

Extensive Experience

Waukesha Bearings has extensive experience designing Maxalign bearings into new equipment as well as retrofitting into existing machines.

Since 1983, we have supplied more than 150 Maxalign designs for more than 2,000 applications.

Typical Applications

- Large-frame gas turbines

- Large-frame steam turbines

- Turbo-generators

- Synchronous clutches