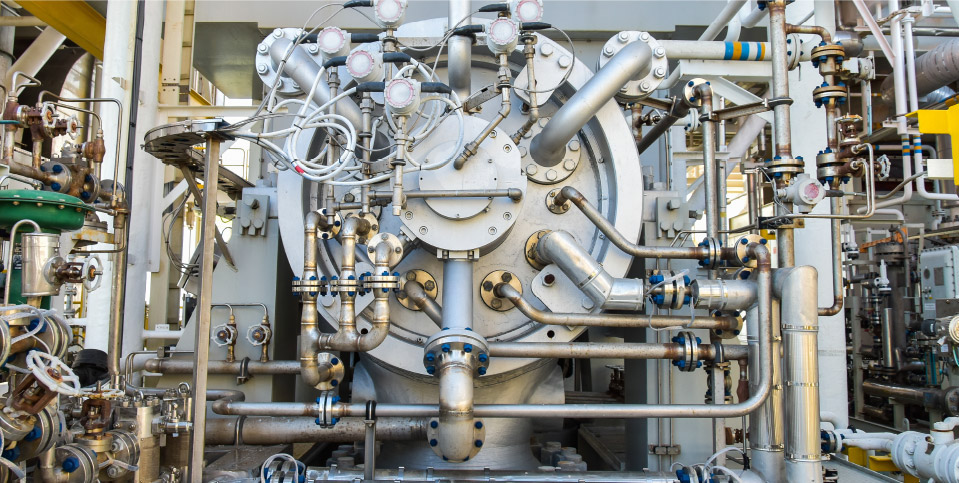

Tilt Pad Journal Bearings

Dynamic conditions of high-speed axial and centrifugal compressors often necessitate the use of tilting pad journal bearing technologies. Design features such as ‘Directed Lubrication’ and specialized materials such as copper chrome (CuCr) backing allow us to maximize efficiency.