Magnetic Bearings

Superior Performance

For more than three decades, Waukesha Magnetic Bearings has applied proven magnetic bearing technology to advance the performance of rotating equipment. We lead the industry in custom-engineered active magnetic bearing (AMB) systems for large turbomachinery and high-performing rotating equipment.

Our robust AMB systems have achieved 99.9% availability without special redundancy provisions, making them the standard for mission-critical applications. We leverage the intelligence of magnetic bearing systems and the remote connectivity capabilities of our third generation controllers to allow for machine commissioning, diagnostics and adjustment on-demand from a remote location.

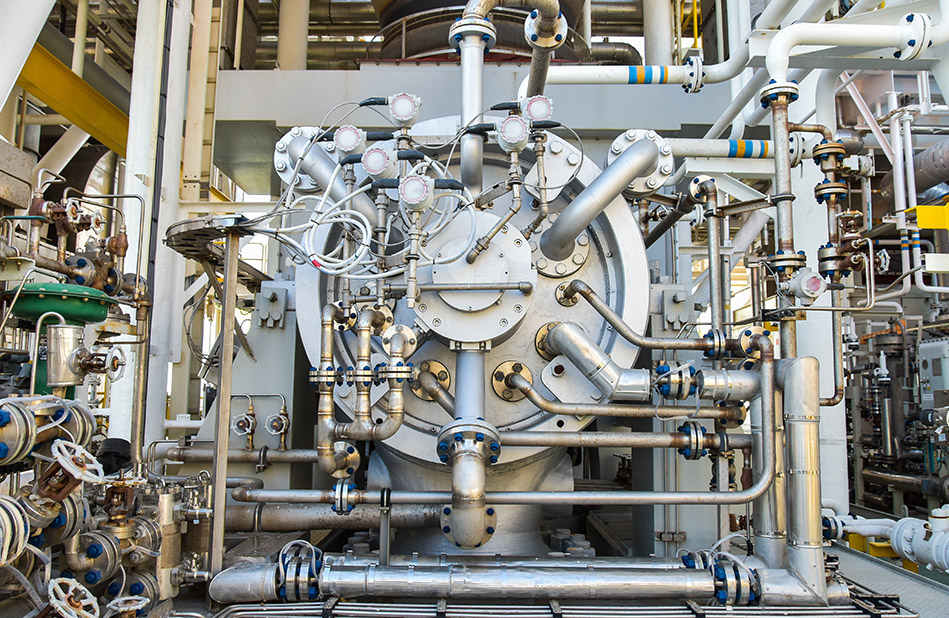

Serving Demanding, Remote Locations

The high reliability and availability of Waukesha AMBs, combined with the capability for remote support, make our systems particularly suitable for remote, unmanned locations.

In addition, the elimination of the oil system inherent in the AMB design offers environmental benefits and reduces the overall footprint of equipment.

Common applications include onshore, offshore and subsea oil & gas operations; petrochemical processes; nuclear power generation; as well as renewable and developing technologies.

Lower Your Total Cost of Ownership

Advanced AMB technologies eliminate auxiliary equipment, lower energy consumption, minimize maintenance, and maximize reliability, providing cost savings throughout the life-cycle of your machinery.

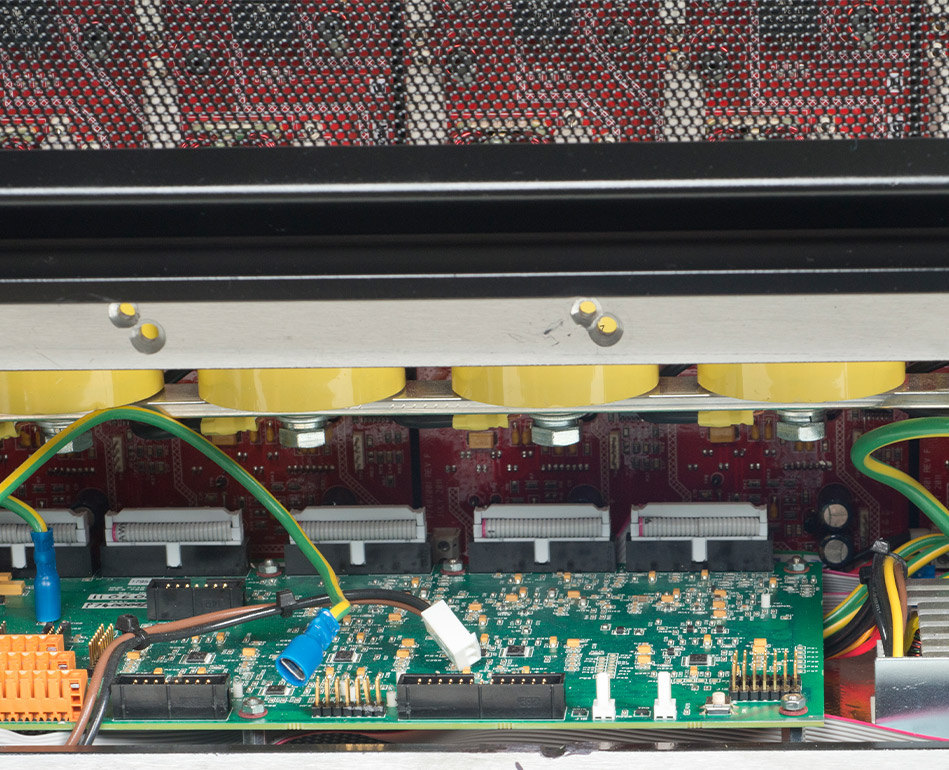

Controllers

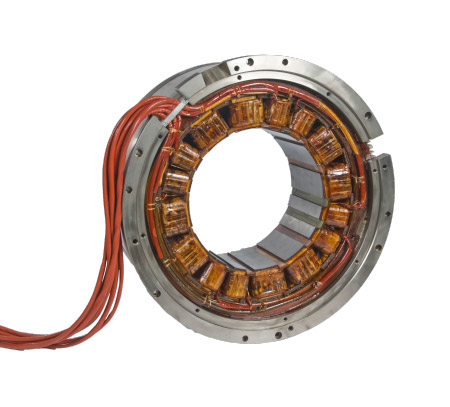

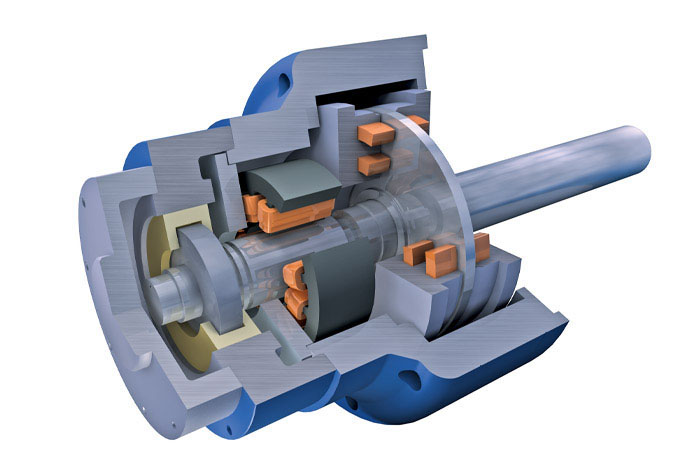

How Magnetic Bearings Work

A magnetic bearing uses electromagnetic forces to maintain relative position of a rotating assembly (rotor) to a stationary component (stator). An advanced electronic control system adjusts these electromagnetic forces in response to forces generated from machine operation.

Related Case Studies

Over 99.9% Availability in Gas Gathering

Exceeding 95% Availability in Pipeline

Canned Magnetic Bearings Achieve 99.9% Availability & Zero Emissions

Improved Reliability & Lower Total Cost of Ownership with Magnetic Bearings

Waukesha Bearings Advantage

- Broad reference list of field-proven systems

- Energy efficient, robust technology with demonstrated availability of 99.9%

- Sophisticated controller functionality for high stability and synchronous control

- AMB controller power rating four times more powerful than the competition

- Skid-mounted AMB controller, certified for hazardous areas

- Leading auxiliary bearing technology for superior investment protection

- Superior service, support and training

- Equip customers to take control of maintenance and commissioning

- Lowest total cost of ownership

Typical Applications

- Compressors

- Sealless motor compressors

- Turboexpanders

- Motors

- Generators

- Boiler feed pumps

- Steam turbines

- Gas turbines

- Blowers

- Helium blowers