Bearing Knowledge

How Fluid Film Bearings Work

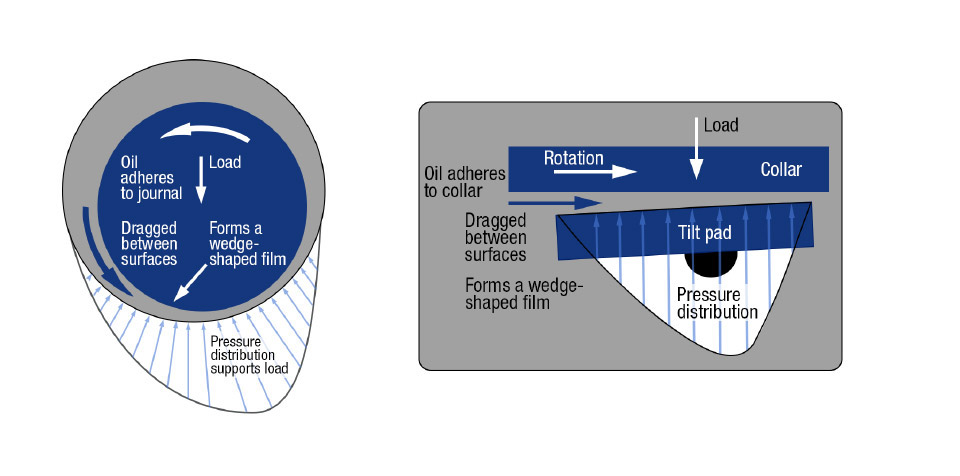

In a fluid film bearing, the stationary and rotating surfaces are separated by a thin film of lubricant, such as oil, air, water or process fluid. In a hydrodynamic fluid film bearing, the film pressure that separates the surfaces is created by the relative motion (rotation) of the surfaces as the lubricant is pulled into a converging geometry between the surfaces. No contact of the surfaces takes place except during start-up and shutdown.

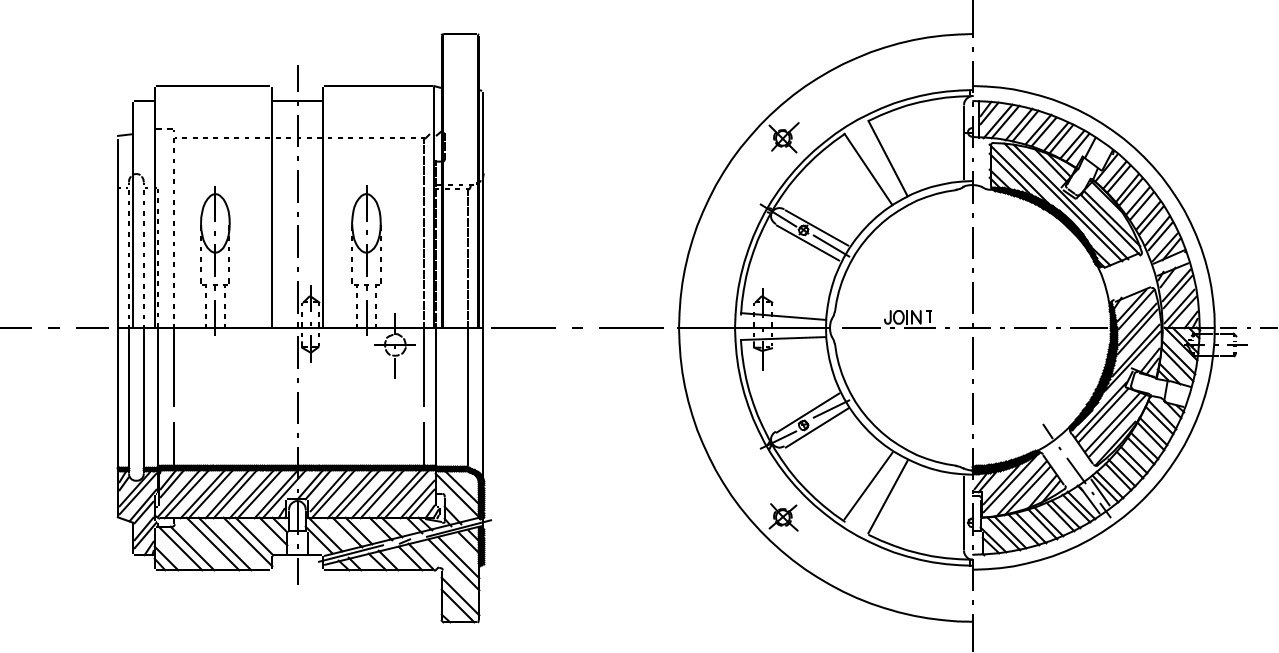

Fluid Film Bearing Design

Both mechanical design and material selection are critical for optimized bearing performance. Click below to read more about the factors that influence design choices.

The Role of a Squeeze Film Damper

While fluid film bearings provide a significant amount of damping, it may not be sufficient for all rotating machinery. An additional means of increasing “effective” damping may be needed.

A squeeze film damper is a layer of film between the bearing and the housing that softens the bearing support to increase damping effectiveness.

Fluid Film Bearings vs. Rolling Element Bearings

A key difference between rolling element and fluid film bearings is the expected life of the bearings. Rolling element bearings typically have a predictable life based on the operating conditions (the calculated L10 life). Fluid film bearings, when properly designed and maintained, can operate for decades.

How Active Magnetic Bearings Work

A magnetic bearing is an oil-free bearing system that uses electromagnetic forces to maintain relative position of a rotor to a stator. An advanced electronic control system adjusts these electromagnetic forces in response to forces generated from machine operation.