Fluid Film Bearing Design

The Right Solution

Having the right bearing for your equipment, your application and your operating environment is essential to the successful operation of the equipment.

Waukesha Bearings pairs carefully selected materials with a mechanical design that delivers optimized performance of the bearing.

Material Selection

Material selection can be affected by load, speed, operating temperature, insulation requirements, and lubricant type and cleanliness. Depending on the requirements, options include babbitt, bronze, aluminum tin, polymer, ceramic or cermet, and diamond.

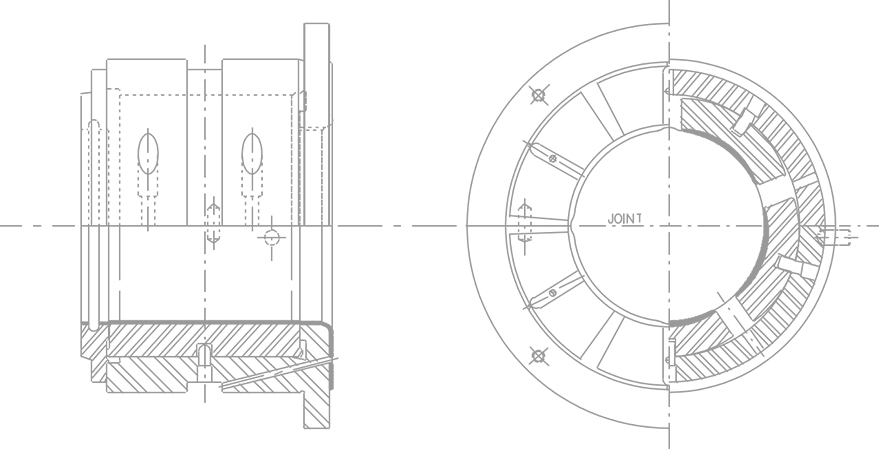

Mechanical Design

A fluid film bearing designer must not only consider the proper sizing of the bearing to handle the loads and minimize the power loss but also incorporate features such as surface geometry, tilt pad design and lubrication method to optimize the formation of film and the bearing performance.