News

Polymers Enhance Design of Hydrodynamic Bearings

By Guy Pethybridge, Waukesha Bearings

Published in International Oil & Gas Engineer, February 2005

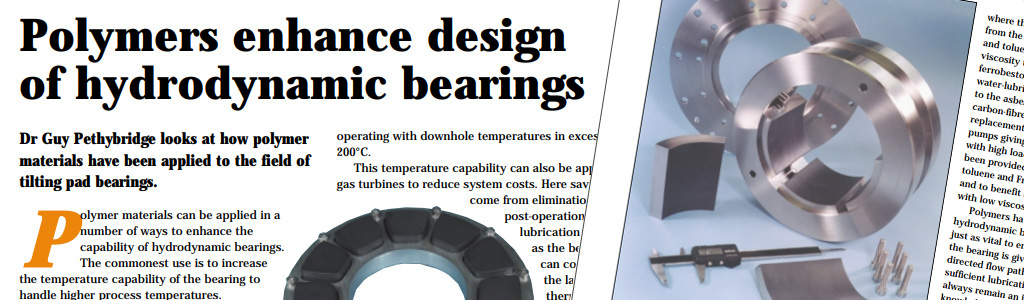

Polymer materials can be applied in a number of ways to enhance the capability of hydrodynamic bearings. The commonest use is to increase the temperature capability of the bearing to handle higher process temperatures.

Polymer-lined thrust bearings have been a vital component in borehole electrical submersible pump systems where ambient temperatures are commonly in the range of 120–180°C. The great depth of the boreholes and the limited space available further increase the stringency of the application, with load requirements of around 8 MPa. Recent innovations have seen new applications operating with downhole temperatures in excess of 200°C.

This temperature capability can also be applied to gas turbines to reduce system costs. Here savings come from elimination of the post-operation lubrication system as the bearings can cope with the large thermal effect resulting from process heat soaking back along the shaft to affect the bearings.

To continue reading about the benefits of polymer bearing materials, download the article below.