ARES AMB Turboexpander from L.A. Turbine

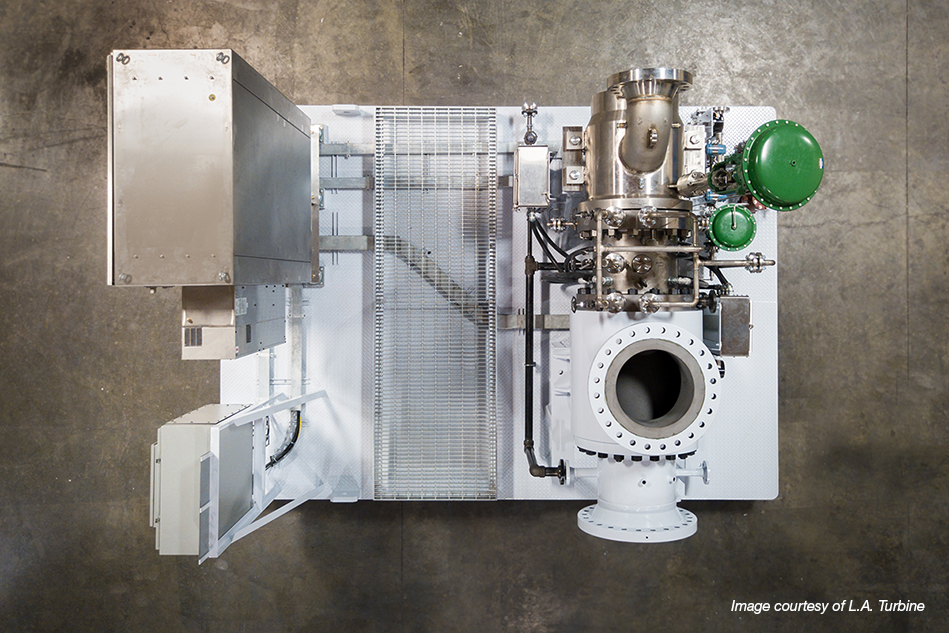

Designed for Natural Gas Processing

The ARES AMB turboexpander-compressor, designed for natural gas processing plants ranging from 60 to 300 MMSCFD, employs active magnetic bearing (AMB) technology to achieve a small, modular footprint, remote AMB commissioning and monitoring, less ongoing maintenance, and greater performance flexibility than a traditional oil-lubricated bearing system.

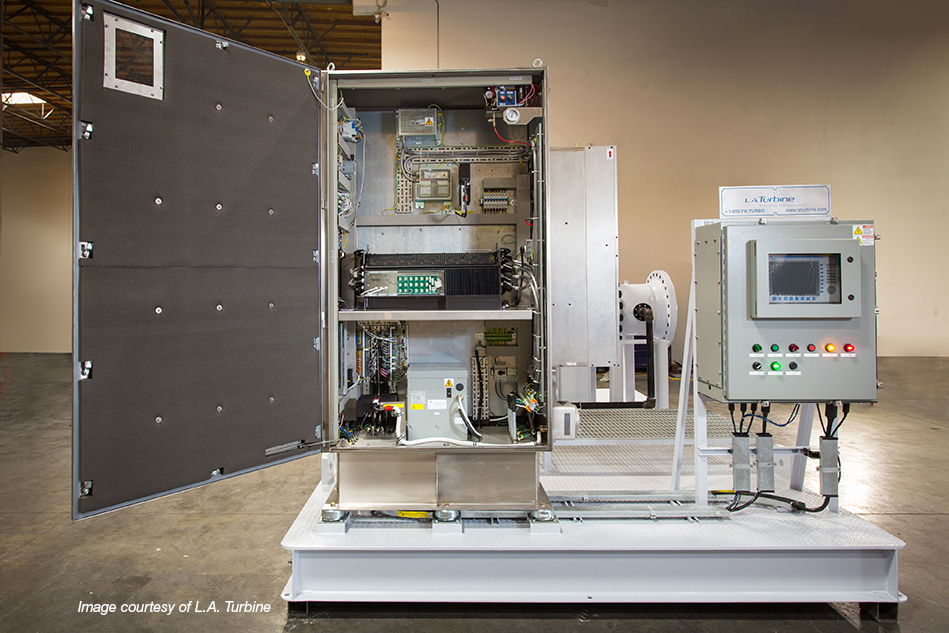

Industry-First Skid-Mounted AMB Controller

The skid-mounted AMB controller is certified for Class 1, Div 2 hazardous area installation through the UL Hazardous Area Panel Builder Program.

The on-skid design provides a condensed footprint and eliminates costly cabling materials, design and installation, while the advanced digital signal processors and control algorithms of the Zephyr® 5-axis controller allow secure remote connectivity for commissioning, monitoring and tuning.

Lower Your Total Cost of Ownership

Advanced AMB technologies eliminate auxiliary equipment, lower energy consumption, minimize maintenance, and maximize reliability, providing cost savings throughout the life-cycle of your machinery.