Auxiliary bearings prevent damage to machine components in the unlikely event of system malfunction.

Auxiliary Bearings

Proven Backup

In an active magnetic bearing system, auxiliary bearings support the rotor when the machine is stationary, accommodate overloads, and support the rotor in the event of system fault.

Waukesha Magnetic Bearings offers a range of auxiliary bearing options, all of which are backed by a full-speed landing test.

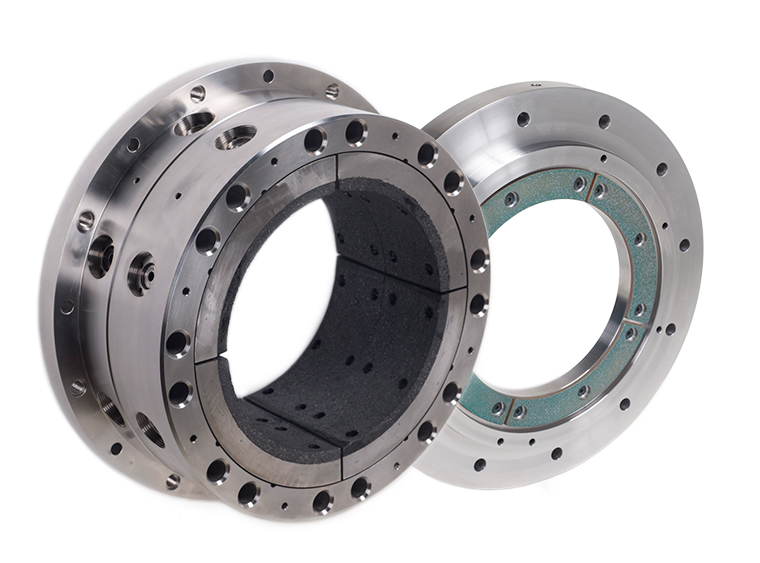

- Stator-mounted ball bearings – a compact design typically suited to high-speed machines and supercritical rotors

- Rotor-mounted ball bearings – a hybrid system typically suited to medium-speed machines and flexible rotors

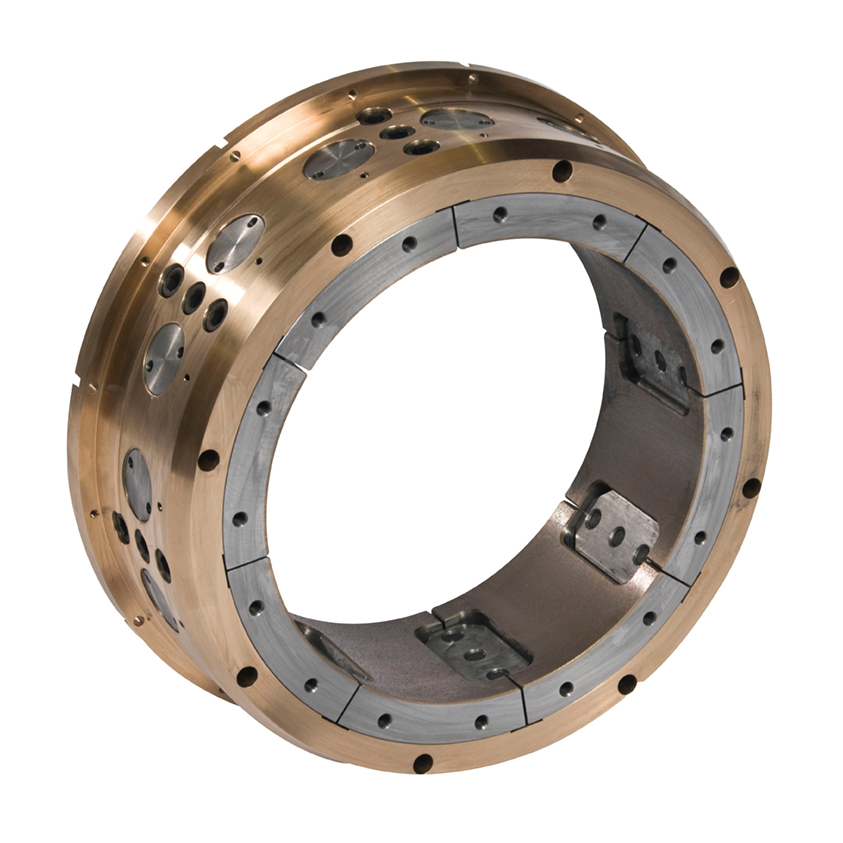

- Bushing type bearings – specialized RDS® auxiliary bearings offering reliable condition monitoring and lower sensitivity to contaminants

Auxiliary Bearing Functionality

RDS auxiliary bearings automatically check clearances to indicate the service condition – reducing the risk of unplanned downtime.