Tilt Pad Bearings

Design Expertise

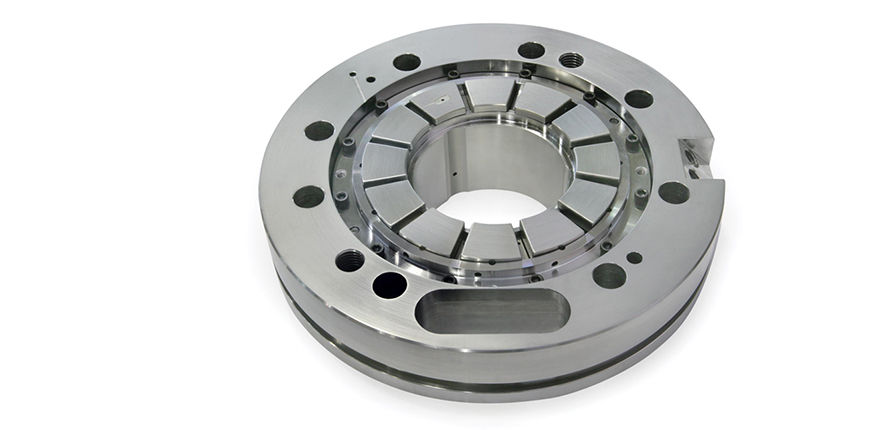

Waukesha Bearings tilt pad bearings are engineered for stability, adaptability and load capacity.

While some loads can be counteracted with fixed profile bearings, tilt pad bearings offer greater customization so that the bearings can be tuned to the conditions of a machine. (Read how fluid film bearings work.) Pad number, pivot type, pivot offset, pad arc, pad material and other features are each modified for the ideal formation of film to meet equipment demands.

Waukesha Bearings combines an extensive database of successful designs with in-house analysis tools and engineer expertise to develop optimized solutions for today’s rotating equipment.

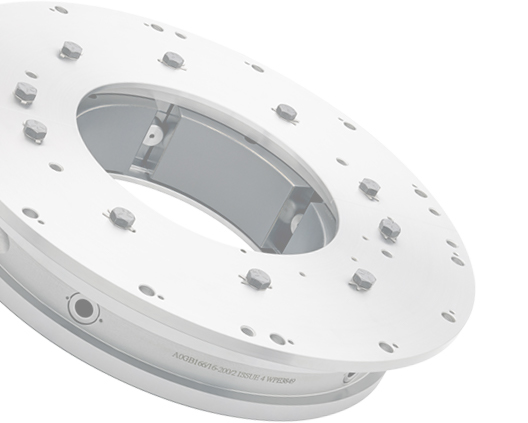

Tilt Pad Journal Bearings

Tilt pad journal bearings can improve stability, adapt to changing conditions, handle misalignment or fine-tune bearing performance.

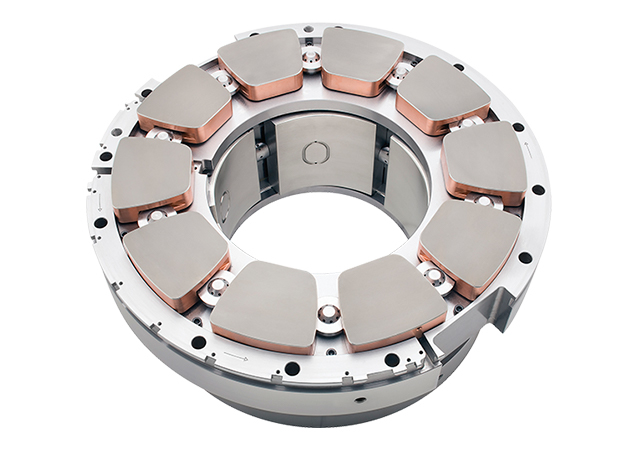

Tilt Pad Thrust Bearings

Tilt pad thrust bearings are typically introduced to accommodate changing conditions or misalignment.