Tilt Pad Thrust Bearings

Meeting Industry Challenges

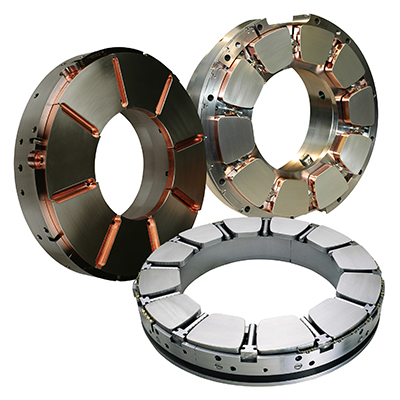

Waukesha Bearings tilt pad thrust bearings, available with or without equalizing links, are designed to transfer high axial loads from rotating shafts with minimum power loss, while simplifying installation and maintenance.

Patented design features allow for optimized performance in a variety of applications and address industry-wide challenges such as axial vibration.

Bearing Design

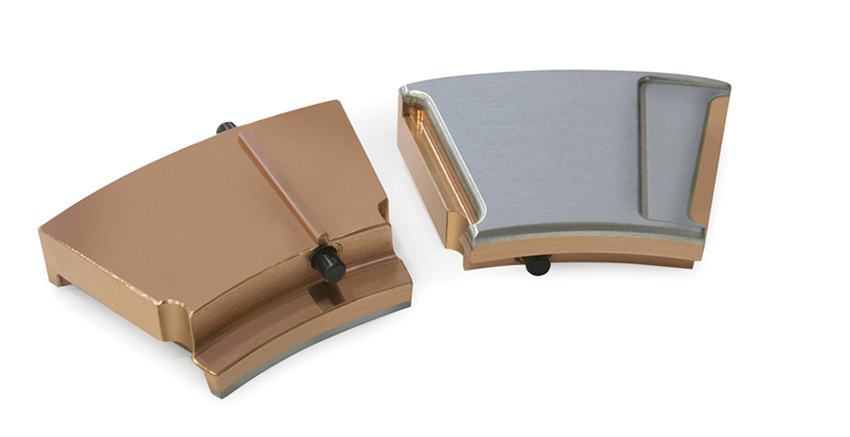

Each bearing consists of a series of pads supported in a carrier ring (retainer). Each pad is free to tilt, resulting in a self-forming hydrodynamic film. The self-equalizing design balances the load between the pads and accommodates misalignment or deflection between the bearing and collar.

The carrier ring may be in one piece or in halves, and the size and number of pads are selected to suit the operating conditions. In addition, pads can be supplied with center pivots for bi-directional running or offset pivots for increased load capacity and lower pad temperatures.

Temperature sensors are typically installed in two pads per thrust bearing.

Lubrication Systems

Flooded Lubrication

The conventional method of lubricating tilt pad thrust bearings is to flood the housing with oil, using an orifice on the outlet to regulate the flow and maintain pressure. To minimize leakage, seal rings are required where the shaft passes through the housing.

‘Directed Lubrication’

Where mean sliding speeds in excess of 50 m/s are expected, the high power losses caused by turbulence in the oil in flooded lubrication systems can be largely eliminated by employing the Waukesha Bearings system of ‘Directed Lubrication’.

As well as reducing power loss by (typically) 50%, ‘Directed Lubrication’ reduces bearing surface temperatures and in most cases oil flow. No seal rings are required on the shaft.

Self-equalizing thrust bearings are typically supplied with ‘Directed Lubrication’ even at relatively low sliding speeds to avoid the need for oil seals.

Advantages

- Proven designs for non-equalizing and self-equalizing tilt pads

- Compact designs to save space

- Pad number, pivot offset and pad material designed to suit specific application

- Pad optimization provides low frictional drag and improved oil circulation

- Industry-standard ‘Directed Lubrication’

Specialty Designs

Tilt Pad Journal Bearings

Waukesha Bearings also provides custom-engineered tilt pad journal bearings, designed to transfer radial loads from rotating shafts with minimum power loss and optimum dynamic characteristics.

Technical Papers

- Performance Characteristics of Two Tilting Pad Thrust Bearing Designs

- Performance Tests on Six-Inch Tilting Pad Thrust Bearings

- Tilting Pad Thrust Bearing Tests – Influence of Oil Flow Rate on Power Loss and Temperatures

- Tilting Pad Thrust Bearing Tests – Influence of Three Design Variables

- Tilting Pad Thrust Bearings: Factors Affecting Performance and Improvements with Directed Lubrication