Journal Bearings

Tilt Pad and Fixed Profile Designs

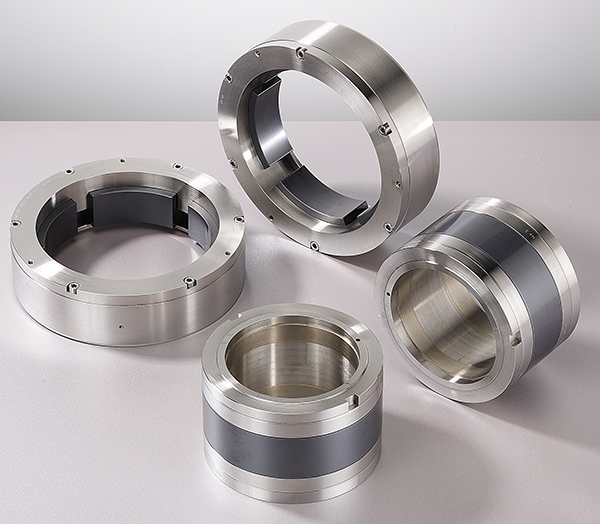

Waukesha Bearings has the most extensive range of journal bearings in the industry, with designs from less than 25 mm (1″) to more than 750 mm (30″) in diameter, available in a wide variety of fixed profile (sleeve) and tilting pad configurations.

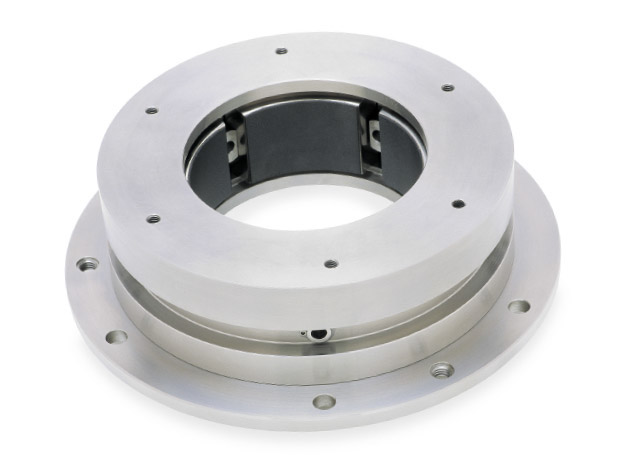

Combination journal/thrust bearing designs are available for applications with limited axial space.

High-Performing Solutions

Engineers at Waukesha Bearings work collaboratively with customers to understand the performance expectations and operating conditions of the bearing and then provide a high-performing solution, manufactured to the highest quality standards in the industry.

Turbomachinery OEMs rely on Waukesha Bearings to deliver the right solution. From small, high speed turbochargers to the world’s largest gas turbine, Waukesha Bearings delivers.

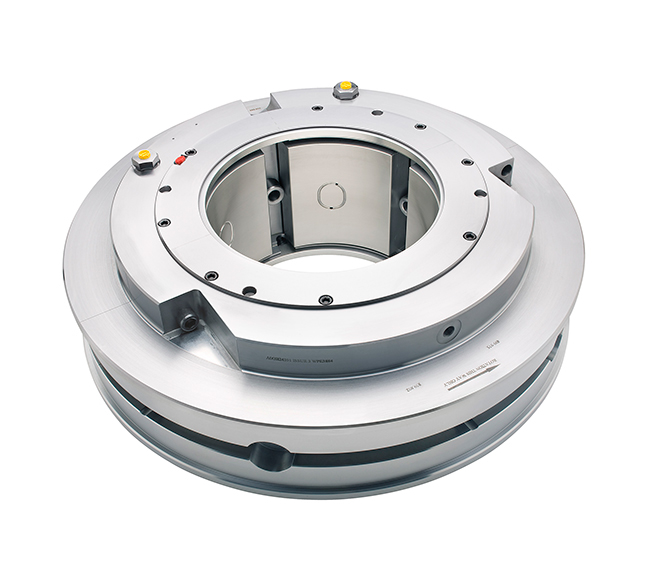

Tilt Pad Journal Bearings

Waukesha Bearings tilt pad journal bearings are designed to transfer radial loads from rotating shafts with minimum power loss and optimum dynamic characteristics.

Fixed Profile Journal Bearings

Through bore profiles, lubrication methods and material selection, Waukesha Bearings medium and thick wall journal bearings can be configured to application-specific performance requirements.

Features and Benefits

Engineers at Waukesha Bearings apply a variety of specialized design features to create custom radial bearing solutions optimized for superior performance.

‘Directed Lubrication’

Minimizes power loss, keeps pad temperatures low and allows for increased load capacity.

Alternative Pad Backing/Surface Materials

Accommodate higher temperatures and dissipate heat more effectively, increasing load carrying capacity.

Pad Pivot Types

Allow for increased capacity (loading) of the bearing with configuration designed to accommodate axial misalignment.

Pad Geometries

Optimize dynamic performance of the machine; increase stability, create optimal stiffness and damping characteristics.

Hydrostatic Lift

Configurations designed to accommodate high loads at machine start-up without sacrificing load carrying capacity.

Advanced Materials

Allow for operation at significantly higher temperatures and thinner films than babbitt.

Instrumentation Options

Supply critical measurements that may indicate machine malfunction (include temperature sensors and proximity probes).