PEEK Bearings

PEEK Bearing Performance

Waukesha Bearings utilizes a proprietary PEEK-based material to enhance fluid film bearing capacity and reliability. PEEK bearings can provide exceptional performance in high ambient temperatures and with low-viscosity lubricants such as water. It is also an electrical insulator and resistant to chemical attack.

With these properties, PEEK components can serve as direct replacements for babbitt components or be incorporated into new designs to extend operating limits.

PEEK Bearing Advantages

The application of engineered polymer on tilt pad thrust and journal bearings provides a number of application benefits.

- Operation with thinner hydrodynamic films for:

- High load capacity – up to 10 MPa (1500 psi)

- Reduced power loss – up to 30% savings

- Operation with low-viscosity lubricants

- Higher temperature capabilities – up to 250°C (482°F)

- Operation with challenging lubricants and process fluids

- Higher start-up load capability without hydrostatic lift

- Corrosion resistance

- Electrical insulation to prevent damaging currents from passing through the bearing and housing to ground

- Embedability similar to that of babbitt

Read more about these benefits on our Polymer Bearings page >

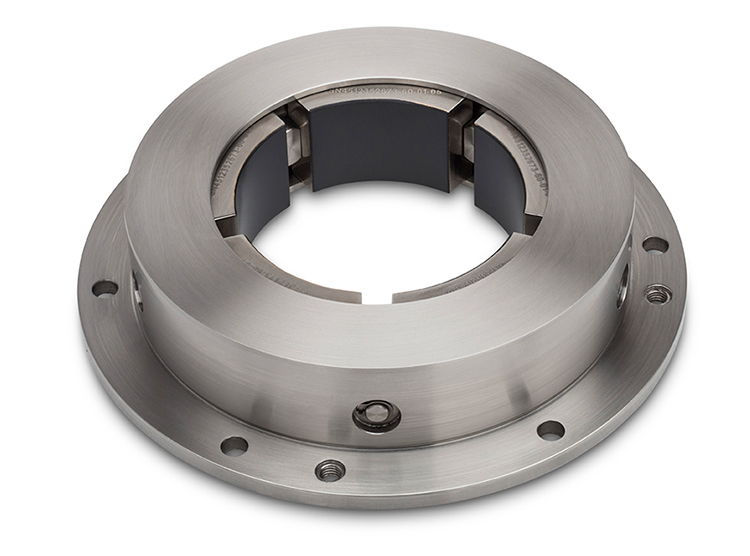

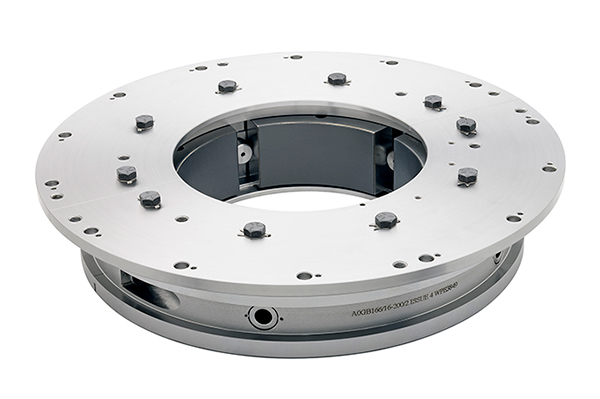

PEEK-Lined and Solid PEEK Bearing Options

PEEK-lined thrust and journal bearing tilt pads are available in the same sizes and mechanical designs as babbitt-lined pads, facilitating direct replacement. The pad backing material may be carbon steel or stainless steel.

In some instances, depending on bearing size and operating conditions, Waukesha Bearings engineers may recommend thrust bearings with solid PEEK pads, known as Hiperax® bearings.

Performance Studies

Heavily Loaded Polymer-lined Journal Bearing

A large tilting pad journal (TPJ) bearing with PEEK-lined pads was tested over a range of operating conditions representative of those experienced on turbo-generators used in fossil fuel power plants. The tests characterized the static and dynamic behavior of the bearing at shaft surface speeds between 40 m/s and 95 m/s and a maximum specific load of 4.75 MPa.

Experimental data along with numerical modeling results, presented at the 2020 ASME Turbo Expo Virtual Conference, confirm the superior performance that can be attained using TPJ bearings with polymer-lined pads at high specific loads.

The paper is titled “Experimental Investigation and Numerical Modelling of a Large Heavily Loaded Tilting Pad Journal Bearing With Polymer Lined Pads”.

Polymer-lined Thrust Bearing in Oil Lubrication

Thrust bearings operating at high speeds and loads can experience high surface temperatures and thin fluid film thickness.

Review test results of polymer-lined thrust bearings subjected to modern turbomachinery conditions compared to babbitt-lined bearings of the same design and under similar conditions in “Experimental Performance Study of a High Speed Oil Lubricated Polymer Thrust Bearing” (Lubricants 3.1 [2015]).

Typical Applications

- Subsea pumps and motors

- Electric submersible pumps

- Reverse osmosis pumps

- Boiler feed pumps

- Mine-dewatering pumps

- Gas turbines

- ORC turbines

- Water-filled motors

- Water-lubricated compressors

Read more about the benefits that PEEK material can provide in these applications on our Polymer Bearings page >