Flexure Pivot Thrust Bearings

Reduce Power Loss, Extend Bearing Life

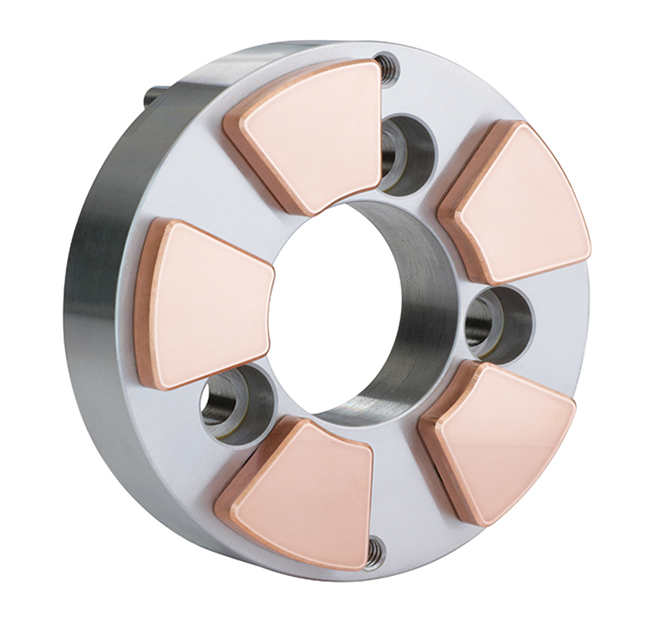

Flexure Pivot® tilt pad thrust bearings reduce power loss and extend bearing life over a wide range of speeds, loads and temperatures.

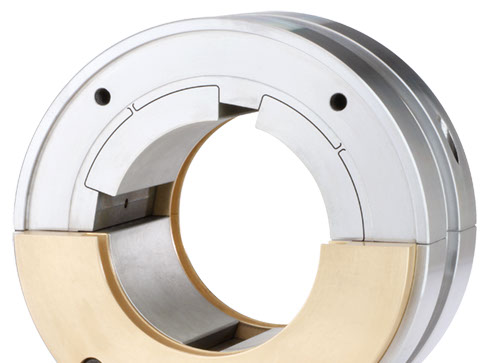

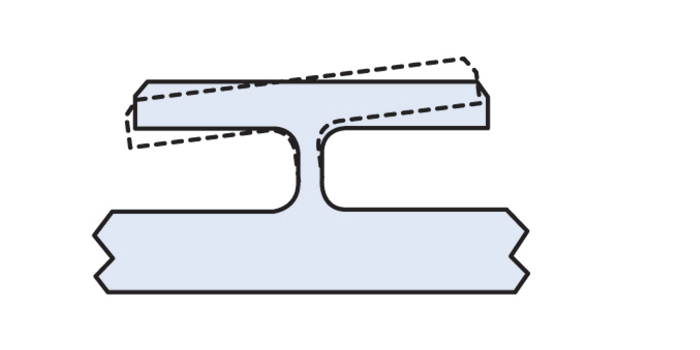

The Flexure Pivot tilt pad design forms a converging wedge through flexure of a post support, eliminating pivot wear and high contact stresses associated with point or line contact tilt pads.

The Flexure Pivot post support is customized for each application to provide an optimum wedge ratio at design load conditions, resulting in an increase in the load capacity and a significant reduction in horsepower loss.

Elimination of Pad Flutter

The rotational stiffness provided in the Flexure Pivot tilt pad bearing eliminates the pad flutter problem that can be experienced on the inactive side of standard tilt pad thrust bearings.

Easy Implementation of Hydrostatic Feature

Offset Flexure Pivot tilt pad thrust bearings can carry higher load capacities in reverse rotation than standard tilt pad bearings, giving them an additional benefit in certain high-load applications. The hydrostatic feature can be utilized through pivot post support.

Static and Dynamic Misalignment Capability

The Flexure Pivot design provides some amount of axial compliance to provide forgiveness of static and dynamic misalignment.

The Flexure Pivot tilt pad is also available in journal bearings.