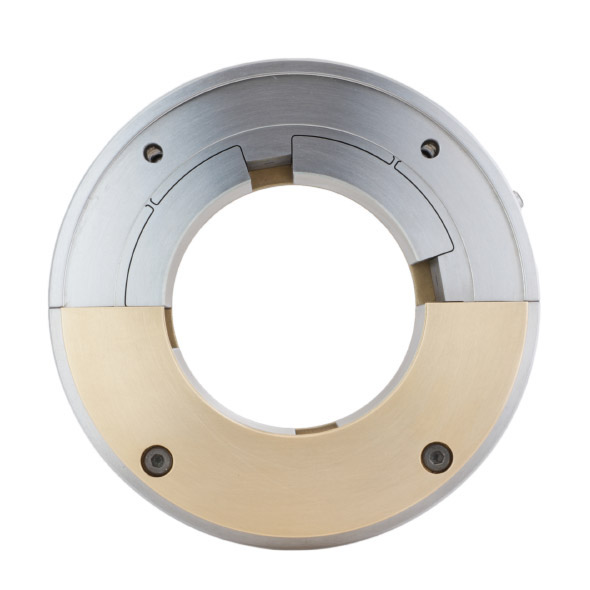

Flexure Pivot Journal Bearings

For High Loads, High Speeds, Small Diameters

Flexure Pivot® tilt pad journal bearings are a leading bearing solution for high-load, high-speed, small-diameter shafts. They achieve low cross-coupling and high stability while eliminating pivot wear, high contact stresses and pad flutter.

Less Tolerance Stack-up

The integral pad-pivot-retainer design of the Flexure Pivot bearing eliminates most manufacturing tolerance stack-up, a critical design parameter which has a direct impact on the rotor’s stability, critical speed, and synchronous response characteristics.

Elimination of Pivot Wear, Contact Stresses

The Flexure Pivot tilt pad design eliminates the pivot wear and brinelling associated with standard tilt pad bearings. This prevents degradation in performance with time, maintains the desired bearing preload, and provides a narrower spread in the stiffness and damping coefficients.

Elimination of Pad Flutter, Spragging

The rotational stiffness increases the pad natural frequency and eliminates pad flutter and spragging that can be encountered on the unloaded pads in standard tilt pad bearings.

The Flexure Pivot tilt pad design is also available in thrust bearings.

Case Study

Long-term Solution to Vibrations

Over a 13-year span, a major South American oil company’s maintenance department fought recurring high vibrations in three gas reinjection compressor trains. A thorough analysis of the compressors and an inspection of damaged components led to a two-part solution.

Typical Applications

- Integrally geared air/process compressors

- Refrigeration compressors

- Integrally geared pumps

- Micro gas turbines

- Expanders

- Gearboxes

Downloads

- Journal Bearing Inquiry Sheet

- Flexure Pivot Bearings Information Sheet

- Bearing Design Reduces Performance Variability (International Oil & Gas Engineer, Aug 2009)