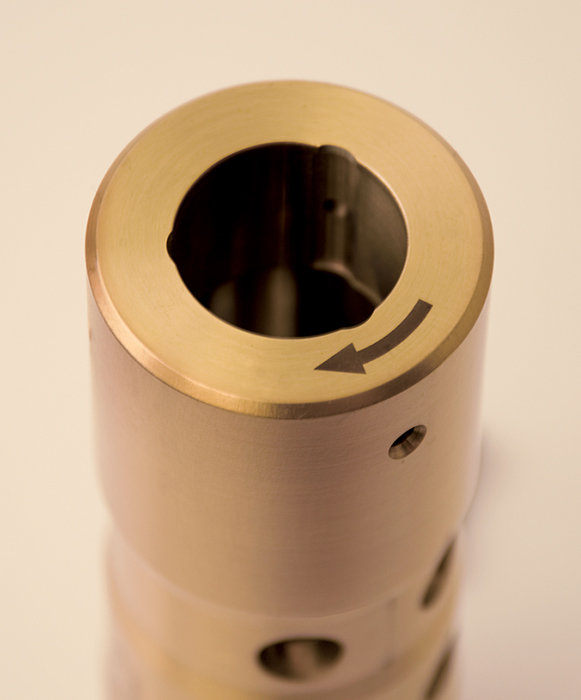

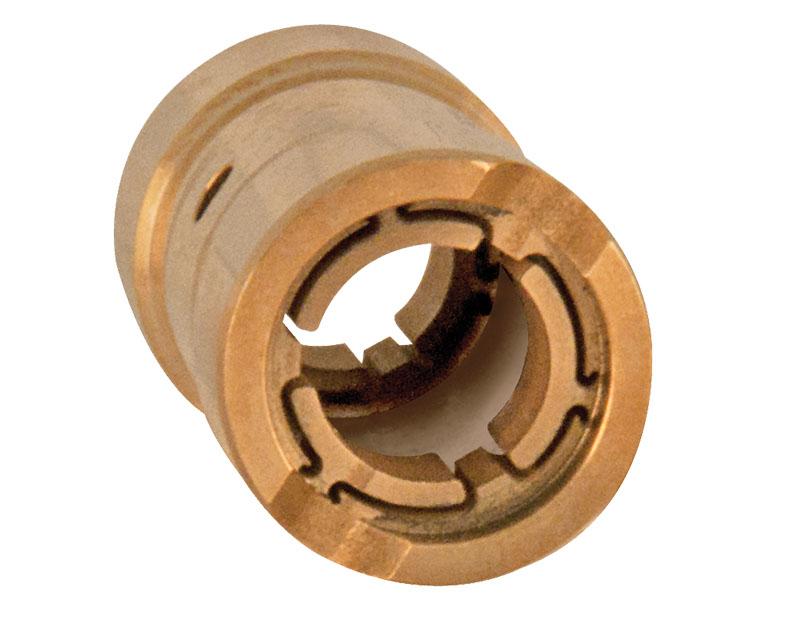

Multi-Lobe Semi-Floating Bearings

Stability and Reliability

Waukesha Bearings provides uniquely engineered multi-lobe semi-floating bearings that improve stability and ensure long life and maximum reliability compared to conventional floating ring bearings.

Using proven technology, MLSF® bearings are designed to run at optimum temperatures with minimal vibrations, extending the life of the equipment and surrounding parts.

Technical Data

- Shaft sizes 13 mm (0.5″) and up

- Bearing L/D as needed

- Single bearings or cartridges

- Typically high dynamic loading – 4.8 MPa (700 psi)

- Temperatures up to 149°C (300°F), with higher temperature available

- Lubrication with multi-viscosity oils

- Various bronze grades available

Typical Applications

- Smaller, high speed turbomachinery

- Turbochargers in large diesel or natural gas engines