Research & Development

Ongoing Bearing Innovation

Waukesha Bearings is committed to ongoing knowledge development and technology leadership to keep our customers competitive and drive the industry forward.

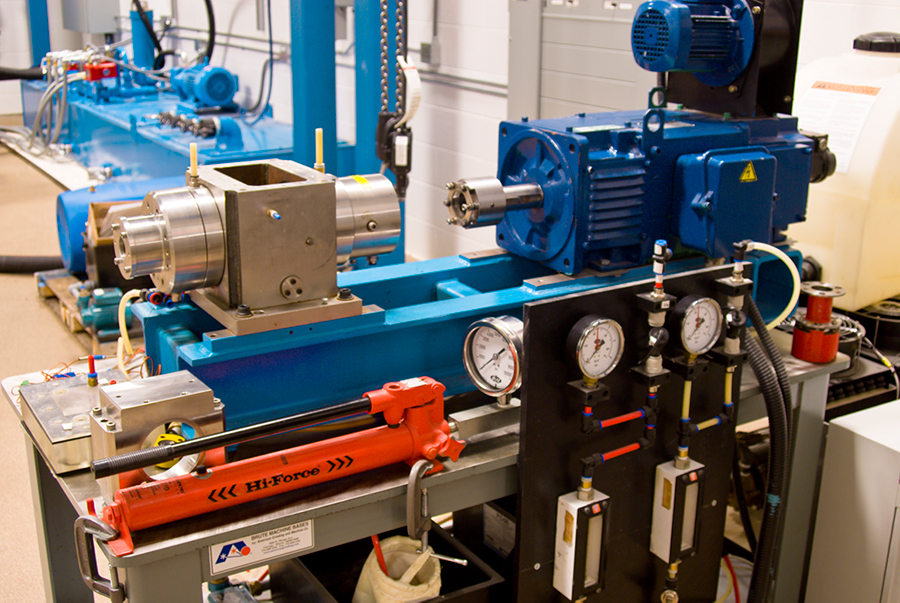

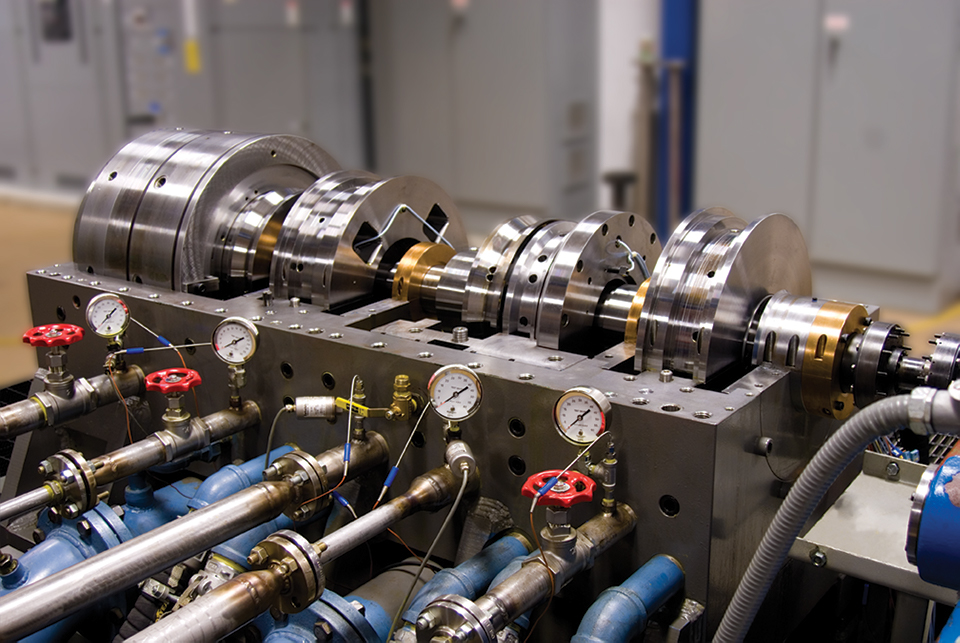

Toward that end, our engineers develop new application solutions and perform design validation, production testing and simulation of field conditions on proprietary test rigs in state-of-the-art R&D laboratories.

Advancing Bearing Design

The Dover Precision Components Innovation Lab provides world-class testing capabilities to:

- Develop and validate fluid film bearing designs, analytical methods and materials

- Evaluate bearing performance

- Prove out solutions under real machine conditions

- Develop next-generation technologies

Our fluid film bearing test rigs can measure the performance of journal and thrust bearings – both large and small, oil- and process-lubricated – at loads and speeds to simulate a wide range of rotating equipment.

Investing in Materials Technology

Dover Precision Components continues to make significant investments in materials development and testing to advance bearing performance and reliability in demanding conditions.

A team of material scientists has been assembled to develop our portfolio of proprietary TruTech® materials, optimize process parameters and enhance product quality. Moreover, our Materials Technology initiative fully integrates materials research with engineering expertise and practical experience in machinery applications to create true value for customers.

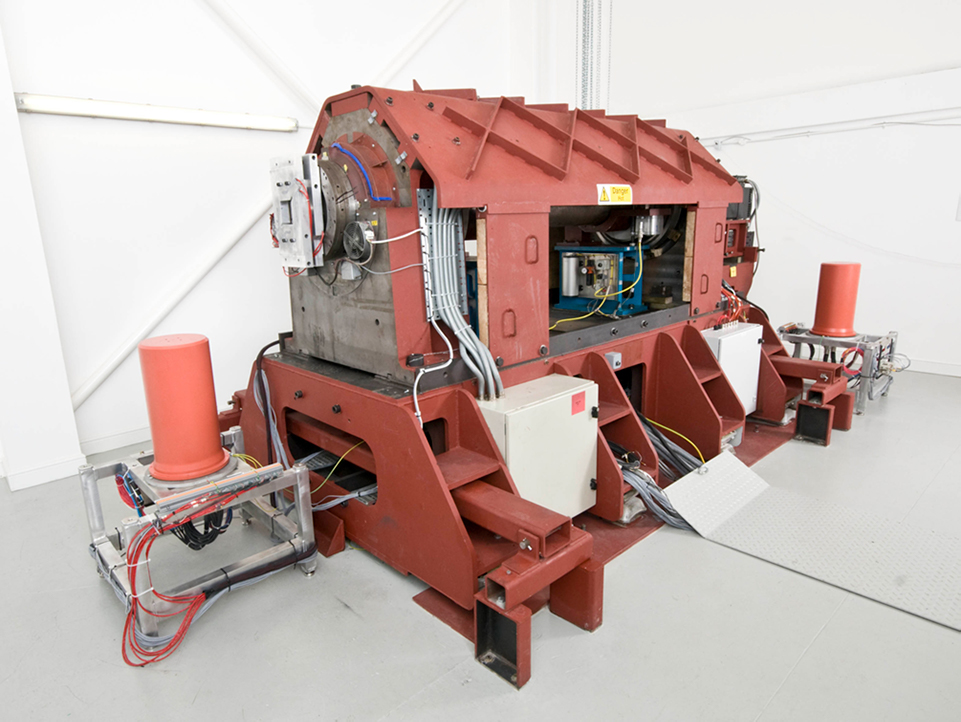

Ensuring Magnetic Bearing Availability

For magnetic bearings, our Red Rig in Worthing, U.K., is the premier test stand in the world. The rig has a 1.5 ton flexible rotor levitated by AMBs. It runs up to 8,000 rpm and can reproduce critical aspects a system will experience in high-speed, high-power turbomachinery.

The Red Rig is one of several test rigs available to simulate the environments in which the magnetic bearing systems will be installed and to validate our technological advances in active magnetic and auxiliary bearing designs, control systems and electronics.

Engineering Expertise

Waukesha Bearings combines extensive application experience and field-testing with a robust development process to deliver the best performing products.